Loading Guide - Pre-tension

Loading Guide - Pre-tension

National

Heavy

Vehicle

Regulator

This guide is part of a series of loading guides that provide tips and tricks to help you understand good load restraint. More detailed information on the principles covered by this guide and comparing the load restraint friction force between two surfaces can be found on page 245 of the Load Restraint Guide 2025.

What is pre-tension?

Pre-tension is the force in the lashing provided by a mechanical tensioner.

Pre-tension is measured in kilograms of force (kgf).

As you tighten the tensioner force is applied to the load through the webbing or chain, clamping the load to the deck of the vehicle.

Why is pre-tension important?

When using the tie-down load restraint method understanding the difference between pre-tension and lashing capacity is critical when designing a load restraint system that’s safe, compliant, and appropriate.

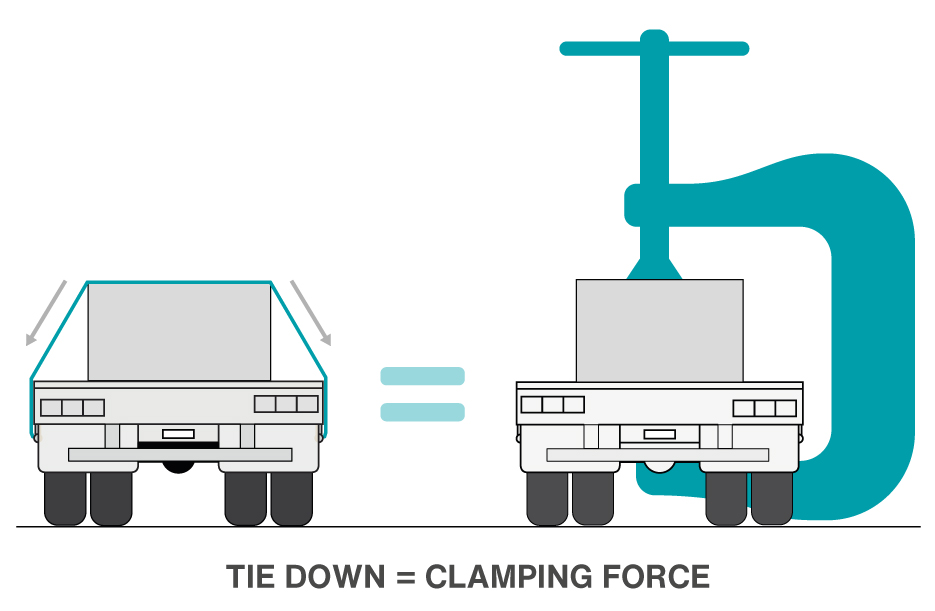

The tie-down restraint method relies on friction to stop the load moving forwards, sideways or backwards. The clamping force created by lashing pre-tension increases the friction.

The more clamping force that’s applied to the load, the less likely the load is able to move.

Pre-tension/lashing capacity?

It’s important to note, that the lashing capacity does not equal the pre-tension force.

Lashing capacity - is the maximum amount of force (in kilograms) that the lashing system is designed to sustain in use. In other words, the point where the lashing or tensioner will fail.

Pre-tension - is the force in the lashing provided by a mechanical tensioner. The amount of clamping force that is applied to the load.

Pre-tension achieved by using a 50mm webbing ratchet tensioning device ranges from typically 300kgf to 600kgf depending on the type of tensioner. Average tensioner pre-tensions for standard equipment are shown in the table below.

For more information refer to page 188 in the load restraint guide.

| Lashing | Size | Tensioner | Pre-tension |

|---|---|---|---|

| Rope | 10mm | Single hitch | 50kgf |

| 12mm | Double hitch | 100kgf | |

| Webbing | 25mm | Hand ratchet | 100kgf |

| 35mm | Hand ratchet | 250kgf | |

| 50mm | Truck winch | 300kgf | |

| 50mm | Hand ratchet (push-up) | 300kgf | |

| 50mm | Hand ratchet (push-down) | 600kgf | |

| Chain | 7mm and above | Turnbuckle | 1,000kgf |

Are all tensioners rated the same?

No, for example a 50mm push-up type hand ratchet will achieve an average pre-tension of 300kgf and a 50mm pull-down type ratchet will achieve an average pretension of 600kgf. These are just average figures listed in the load restraint guide but some devices may have more or less.

Some 50mm ratchets are what we call high-pre-tension ratchets and can achieve up to 750kgf.

Note: the amount of pre-tension achieved through the various tensioning devices is dependent on the persons physical attributes.

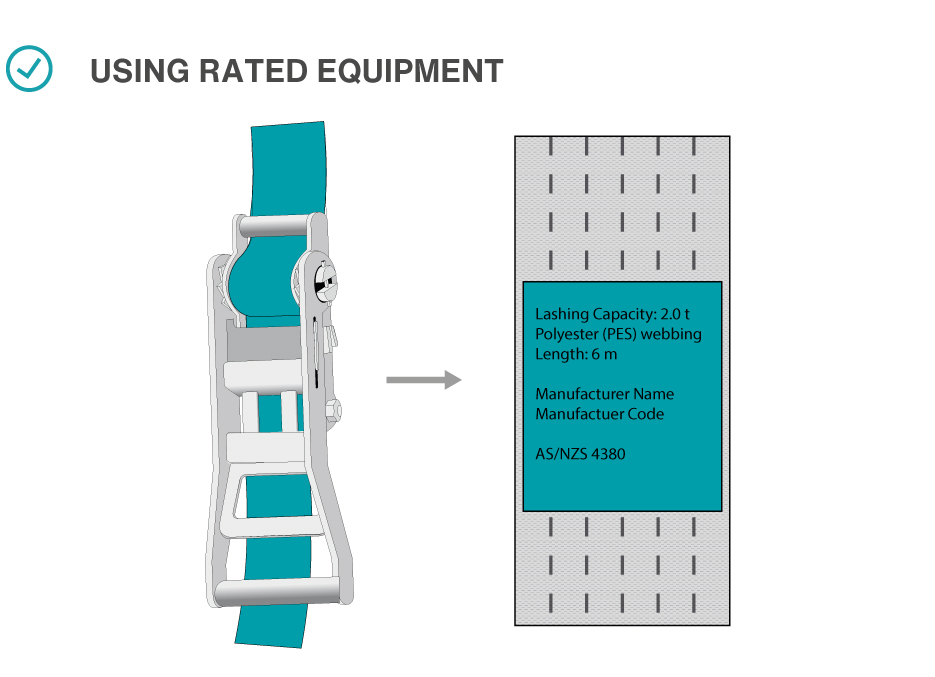

Is the pre-tension rating displayed on the tensioner?

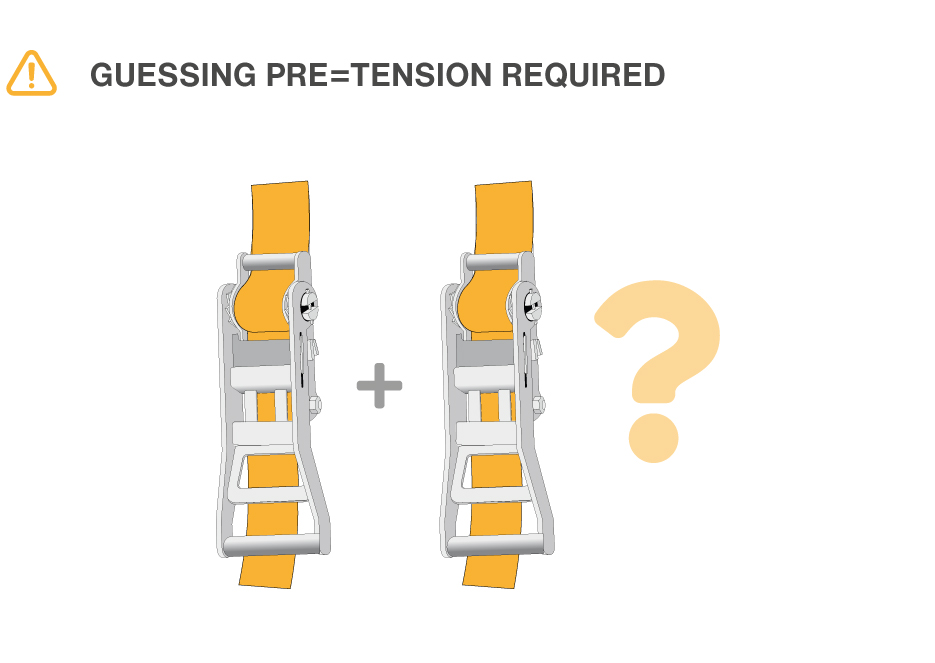

No, many tensioners list the lashing capacity but not the pre-tension. You may need to contact the manufacturer to confirm the pre-tension capability if the information is not readily available on the packaging or online.

There are devices available that are fitted with a visual tension force indicator that shows you when you have reached the desired pre-tension.

The Australian Standard AS/NZS-4380 only requires the lashing capacity to be displayed, not the pre-tension.

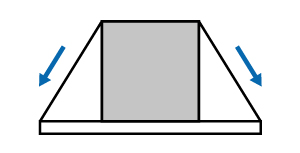

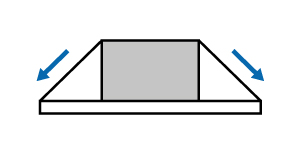

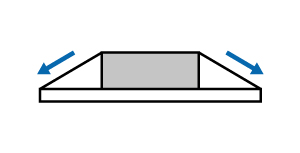

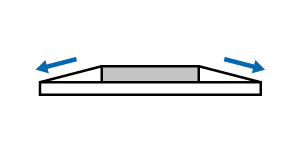

Does lashing angle affect pre-tension?

Yes, the more a lashing is angled away from the load, the less the clamping force. This is called the angle effect.

The lower the lashing angle, the more lashings are required to give the same clamping force. Tie-down lashings are most effective if they are vertical and tight. One strap at 90° is equivalent to four straps at 15°.

| Approximate angle | Tie-down angle effect | Tie-down effectiveness |

|---|---|---|

90° 90° |

1.00 | 100% |

60° 60° |

0.85 | 85% |

45° 45° |

0.70 | 70% |

30° 30° |

0.50 | 50% |

15° 15° |

0.25 | 25% |

Load restraint tables

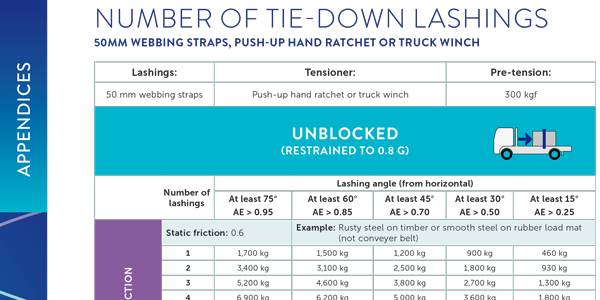

Below is the table for the tie-down restraint method from page 275 of the load restraint guide. The table tells you the lashing type, the type of tensioner, and the nominal pre-tension value for that type of tensioner.

It’s important that you choose a table that’s compatible with the load restraint equipment you are using, in this case we are using a 50mm webbing strap with a push-up hand rachet or truck winch. This information will determine the average pre-tension that equipment can achieve and will ensure the correct amount of lashings is calculated to safely restrain your load.

Tips

Understanding the importance of pre-tension has for effective load restraint is critical when designing a load restraint system that’s safe, compliant, and effective.

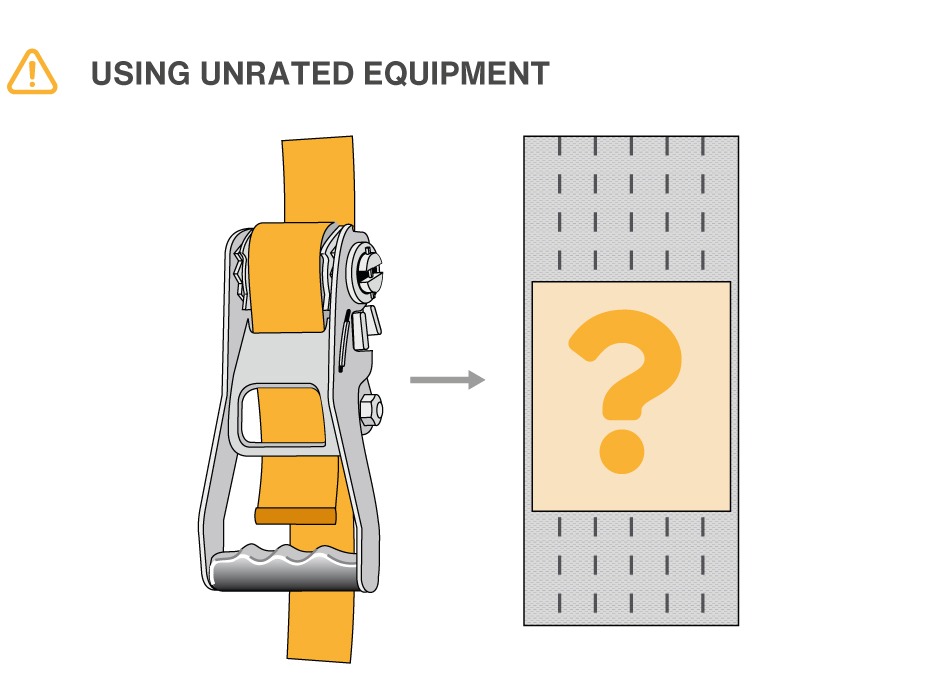

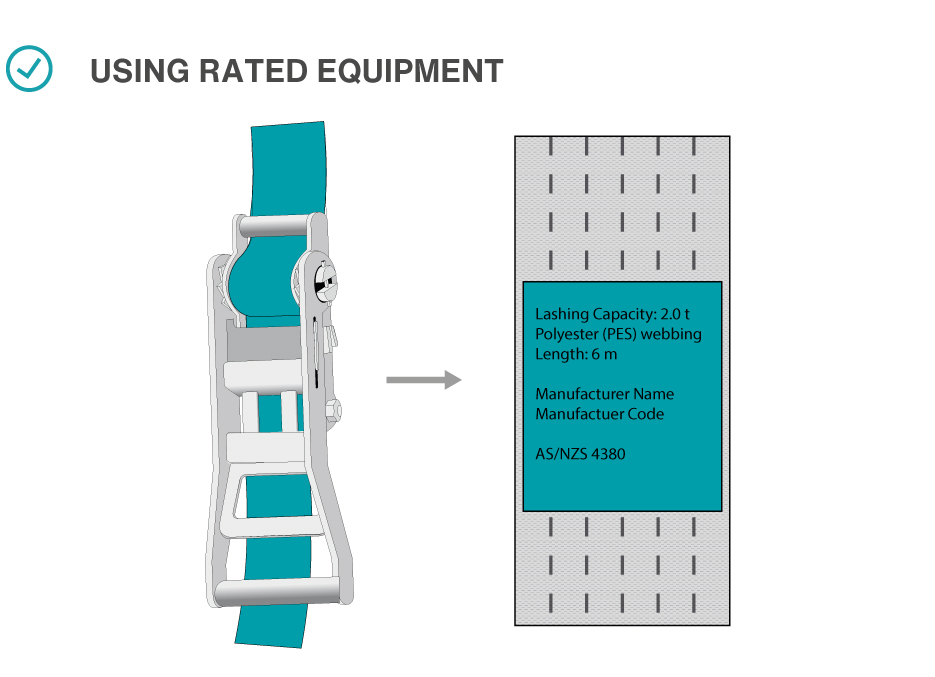

Using non-rated tensioners is a risk because you don’t know what pretension they can achieve. Using rated equipment allows you to select the appropriate tables in the load restraint guide to calculate restraints required.

Risks

Good practice

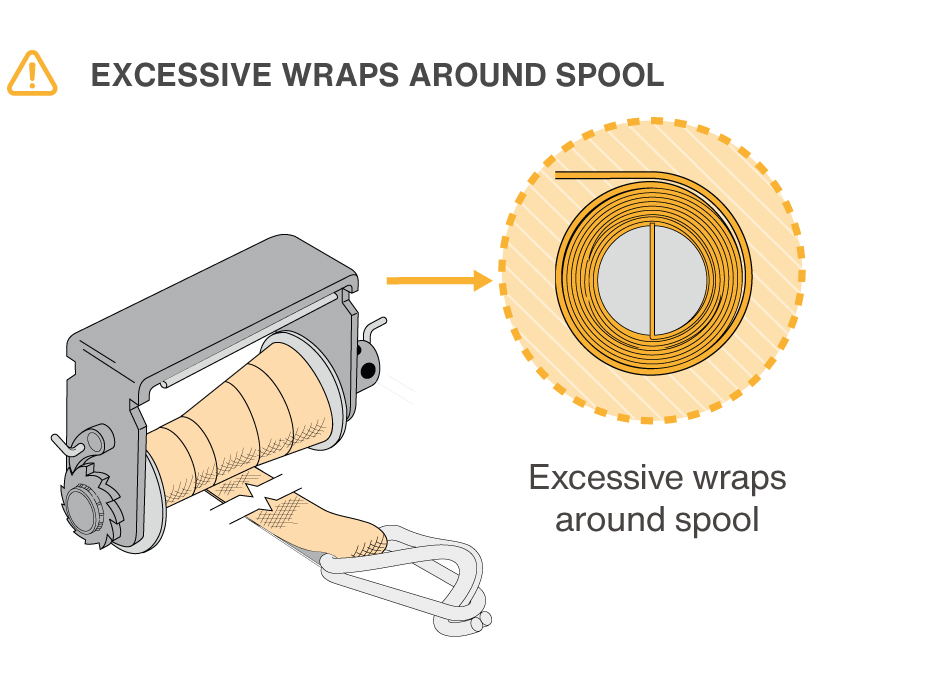

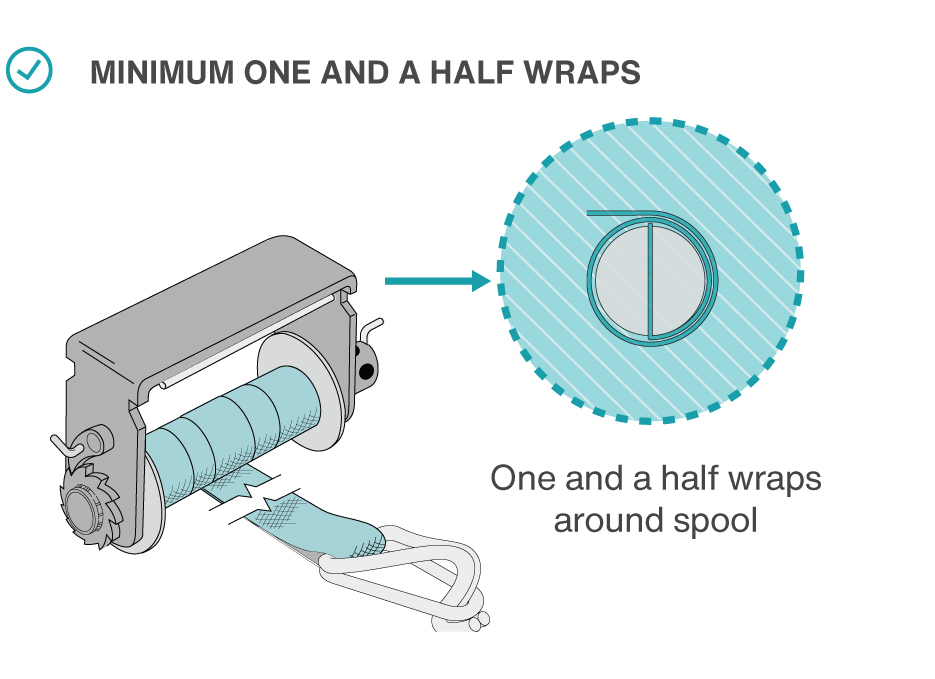

Excessive wraps around the spool can lower the pretension by up to 50%. Ensure there is at least one and a half wraps around spool and no more than three.

Risks

Good practice

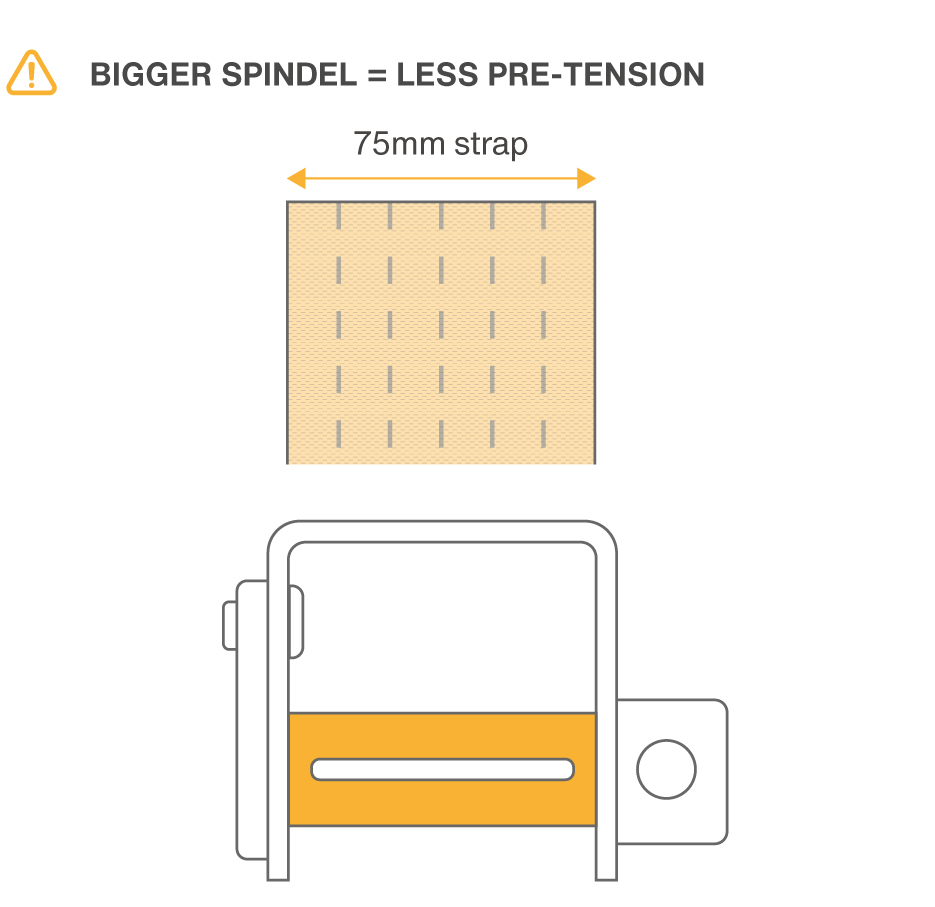

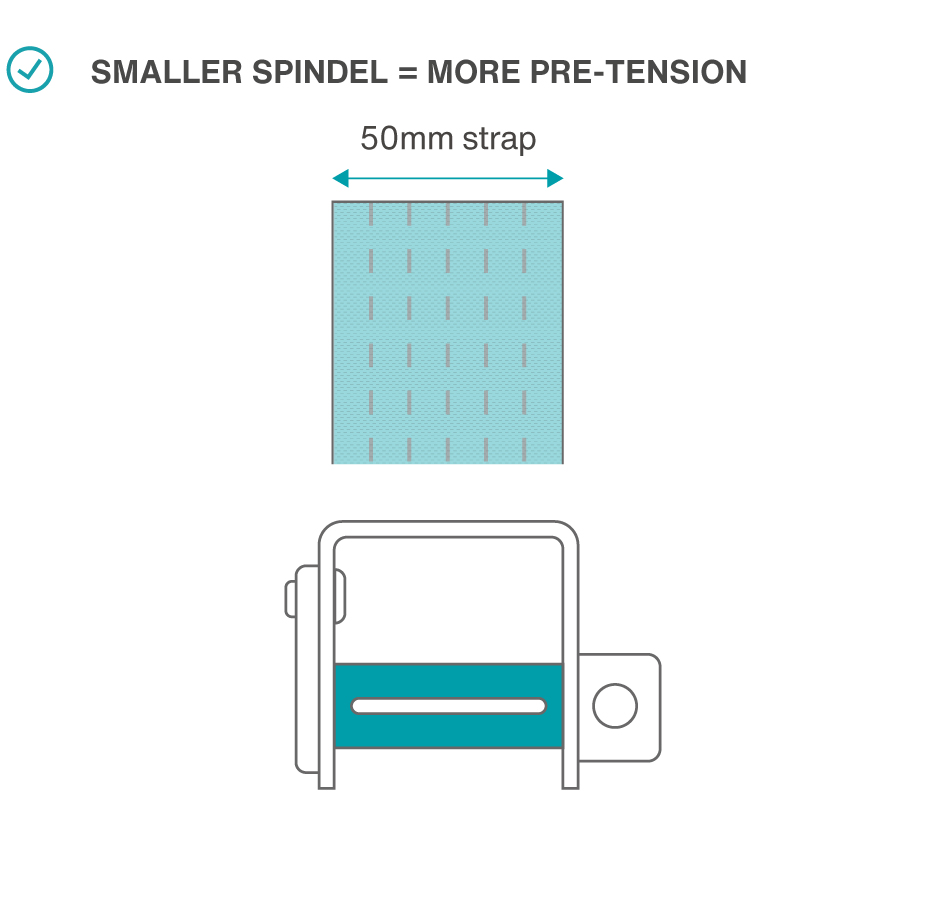

Some 75mm and 100mm strap tensioners may not achieve 600kgf average pre-tension even though their lashing capacity is greater. The relationship between the spindle size and the length of the handle influences the pre-tension. Some high-pre-tension air-driven 75mm and 100mm tensioners can achieve a pre-tension of up to 1500kgf. Always check the rating with the manufacturer before use.

Risks

Good practice

Risks

Good practice

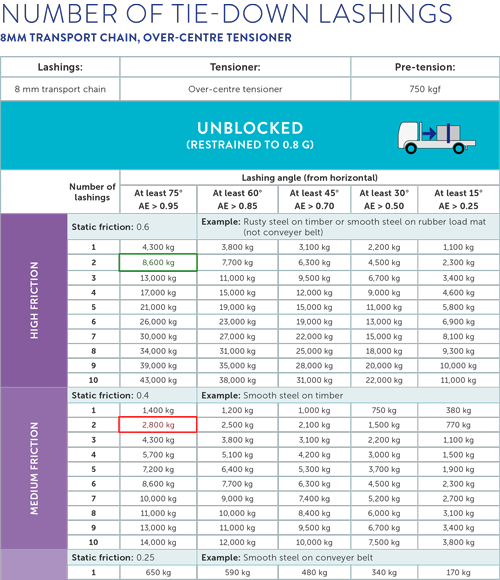

Case study

A heavy vehicle was loaded with a 5-tonne sandstone block.

If this 5-tonne block shifts during transport it can cause vehicle instability. If it falls off the heavy vehicle it could cause serious injury or death to other road users and damage to road infrastructure.

The restraint system only had two 750kgf tensioners providing around half the pre-tension needed to meet the loading performance standards and safely secure the load.

Remember pre-tension is different to lashing capacity.

These devices typically have a lashing capacity of 5-tonne each but the tensioner is only capable of 750kgf pre-tension as specified by the manufacturer.

With reference to page 271 of the load restraint guide:

- Pre-tension - 750kgf max (manufactures rating)

- Not blocked - 0.8g forward restraint (loading performance standard required)

- Medium friction - 0.4µ smooth steel on timber

- Lashing angle - around 75°.

The load restraint system in the picture is compliant for 2.8t maximum.

To better secure this load in relation to pre-tension you could try:

- adding more tensioners thus increasing friction

- using tensioners with a higher pre-tension rating

- blocking the load.

Accessibility tools

Accessibility tools