Loading Guide - Lashing Angle

Loading Guide - Lashing Angle

National

Heavy

Vehicle

Regulator

This guide is part of a series of loading guides that provide tips and tricks to help you understand good load restraint. More detailed information on the principles covered by this guide can be found on page 218 of the Load Restraint Guide 2025.

What is lashing angle?

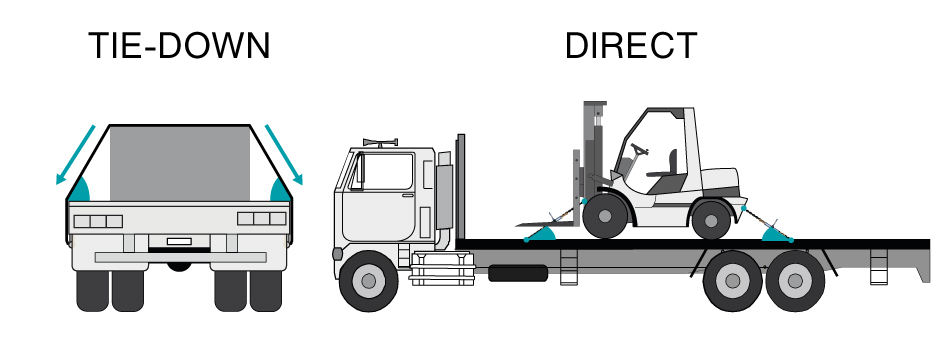

Lashing angle is the angle between the lashing and the vehicle’s loading deck. The lashing angle affects the number of lashings required, which can be calculated using tables in the load restraint guide.

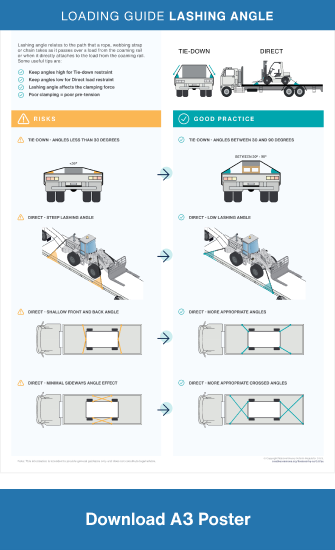

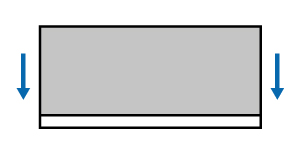

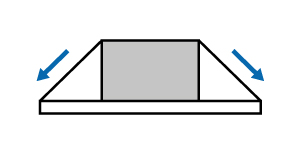

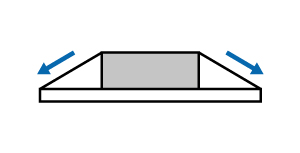

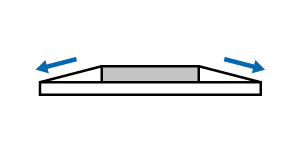

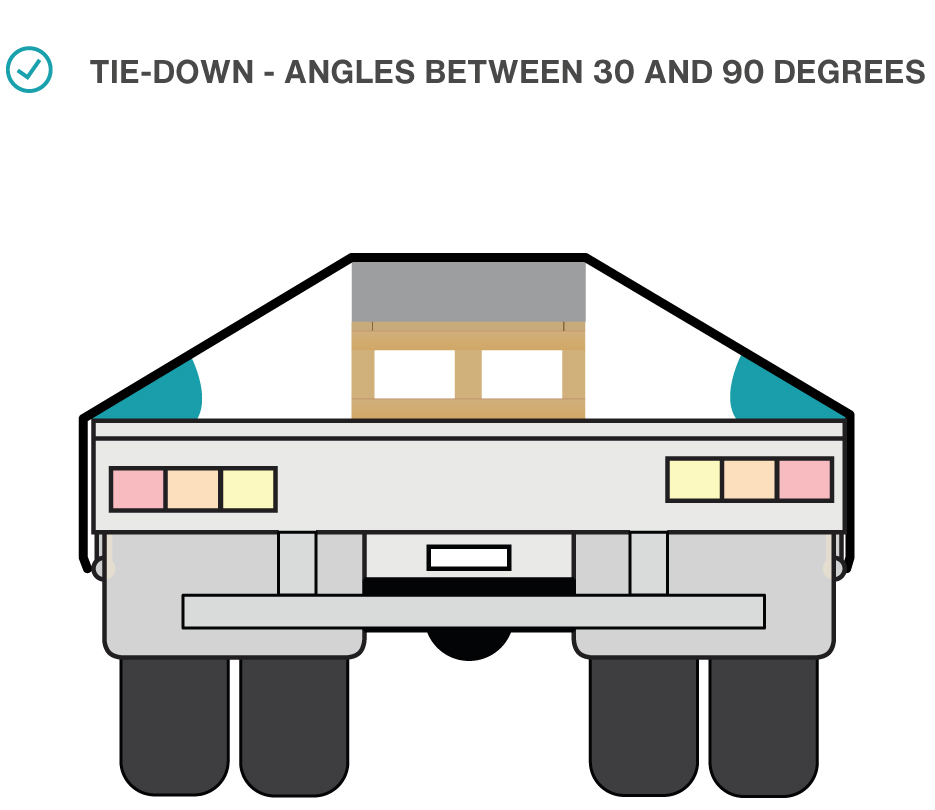

In tie-down restraint the aim is to increase the lashing angle to increase the clamping force (pre-tension) on the load.

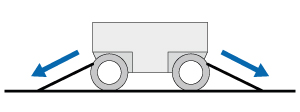

In direct restraint the aim is to keep the angle low and in the direction of the movement.

Why is lashing angle important?

When designing a load restraint system, understanding the lashing angle and the affect it has on the force applied by the lashing is very important. It will assist you in determining the number of lashings required to safely restrain the load.

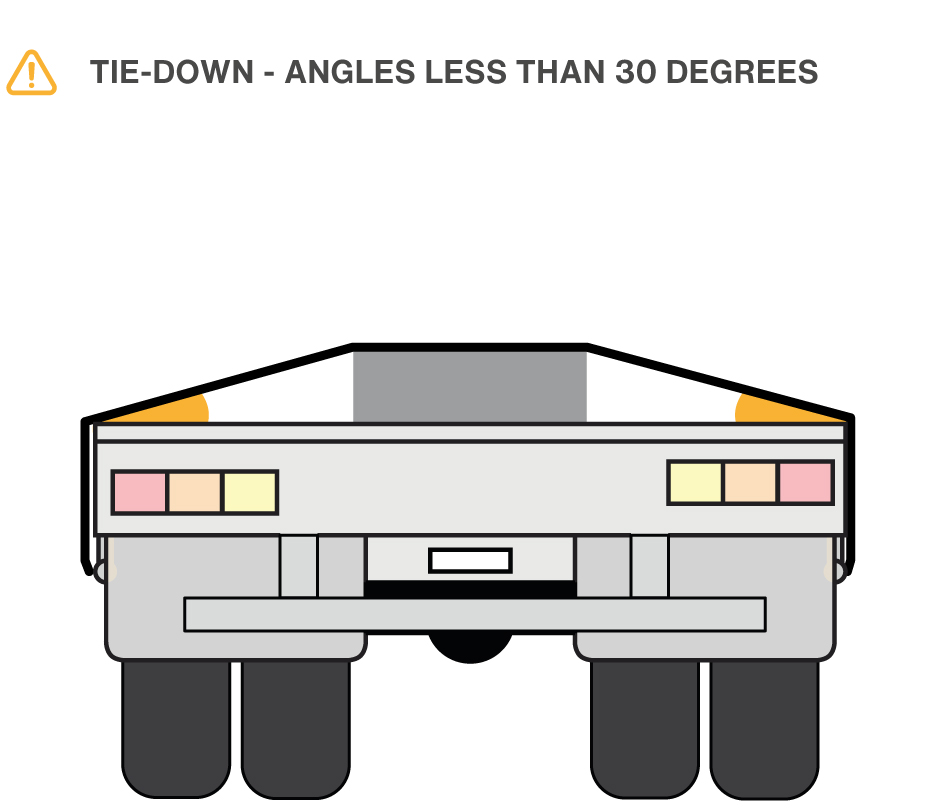

Tie-down method

In the tie-down restraint method, a poor angle effect might require you to add additional lashings to increase the clamping force to prevent the load from moving. In the table to below you can see a lashing at 90° is 100% efficient and will provide maximum clamping force to the load.

As the angle decreases, so does the effect it has on the clamping force. Example, one lashing at 90° provides the same clamping force as four lashing at 15°.

| Example | Approximate angle | Tie-down angle effect | Tie-down effectiveness |

|---|---|---|---|

|

90° | 1.00 | 100% |

|

60° | 0.85 | 85% |

|

45° | 0.70 | 70% |

|

30° | 0.50 | 50% |

|

15° | 0.25 | 25% |

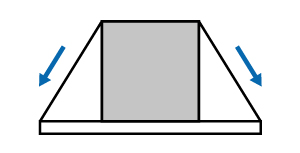

Direct attachment

When calculating the angle effect for direct attachment it’s important to note that the more vertical the lashings, the less effective they are in providing horizontal restraint. This is the opposite to the tie-down method. When using direct attachment, a poor angle effect might require the use of higher capacity lashings or even additional lashings to correctly restrain the load.

As the lashings become more vertical, they become less effective in providing horizontal restraint.

Example, the working capacity of a 3.8 tonne rated chain angled at 25° is reduced to 2.85 tonne. The same chain angled at 60° is reduced to 1.90 tonne. Also, the capacity of lashings that pass over sharp edges like coaming rails, is reduced by a further 25%.

| Example | Approximate angle | Direct lashing angle effect | Direct lashing effectiveness |

|---|---|---|---|

|

25° | 0.90 | 90% |

|

30° | 0.86 | 86% |

|

45° | 0.70 | 70% |

|

60° | 0.50 | 50% |

How do I measure lashing angle?

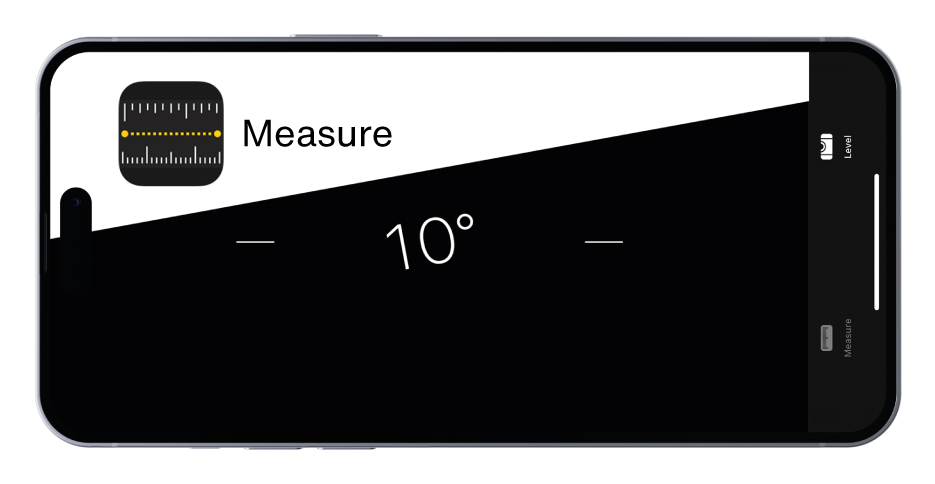

Tie-down method

One of the simplest methods for measuring the angle effect in tie-down is to use an app on your smart phone. Some companies produce small credit card templates the that fit in your wallet. You could also use a spirit level with built in angle indicator.

Regardless of the method, compare the lashing angle to the tables in the load restraint guide to calculate how many restraints are required.

Direct attachment

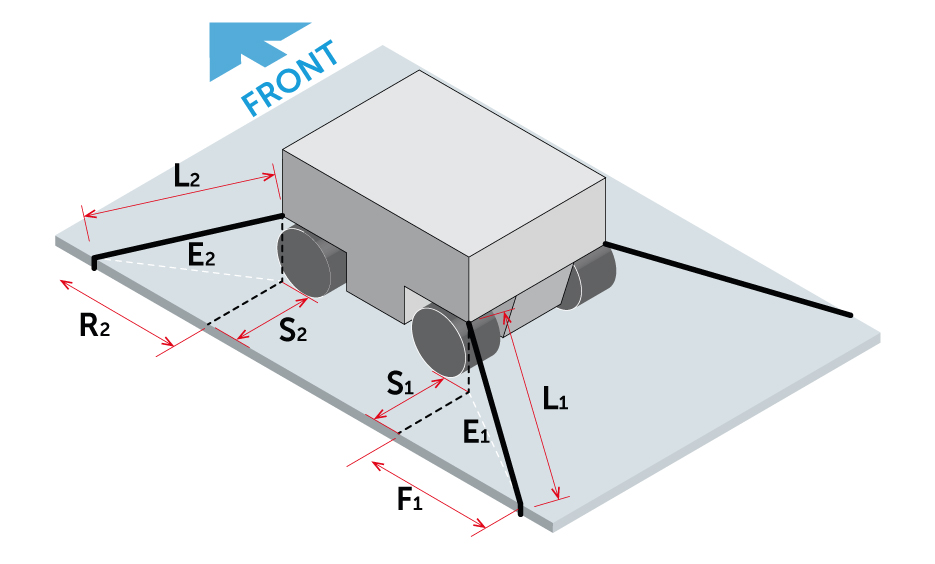

Measuring lashing angle for direct attachment is a little more complicated. There are a number of measurements needed in order to do the calculations for direct attachment.

Read the example below for the simple rule and then read the case studies 5, 6 and 7 in the load restraint guide for larger equipment such as plant.

Additionally training providers and engineers that specialise in load restraint can assist with loading plans and advice on compliance.

Lashing angles, direct attachment, and the simple rule.

The example to below is known as the simple rule in direct attachment and can be found on page 219 of the load restraint guide. It is less accurate and makes some assumptions that may be incorrect.

In this example it assumes the lashings are angled at less than 60° to the appropriate direction of movement. However, lashings used in this way will in most cases be stronger than necessary.

Tips

Lashing angle affects the clamping force and the capacity of the restraint system.

As the lashing angle diminishes so does the angle effect, meaning more lashings or higher pre-tension devices are required.

As the lashing angle increases so does the angle effect. Less lashings are required.

Risks

Good practice

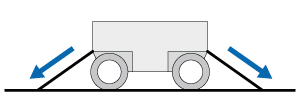

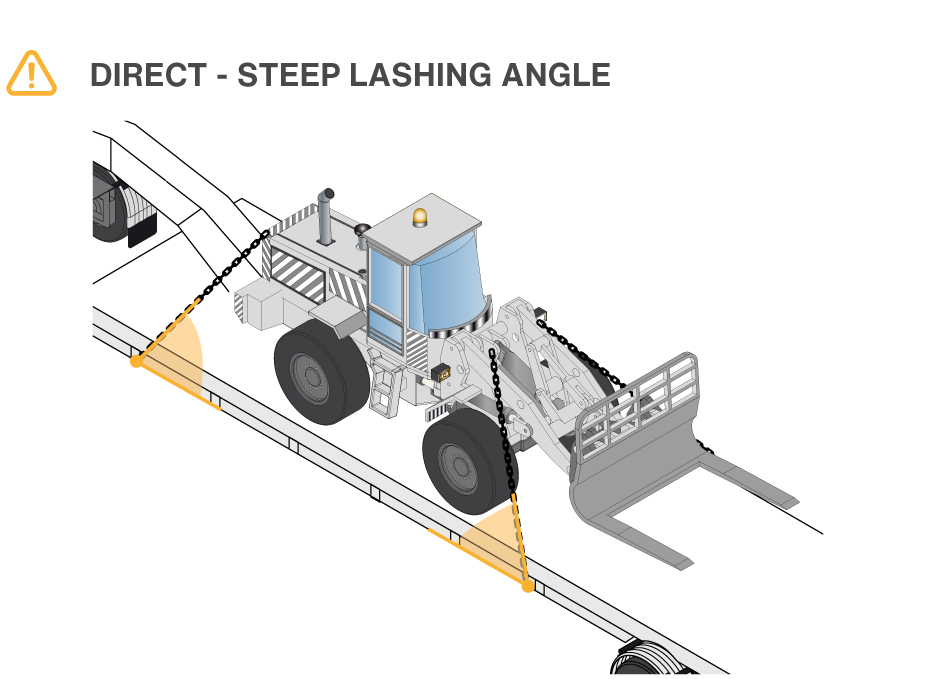

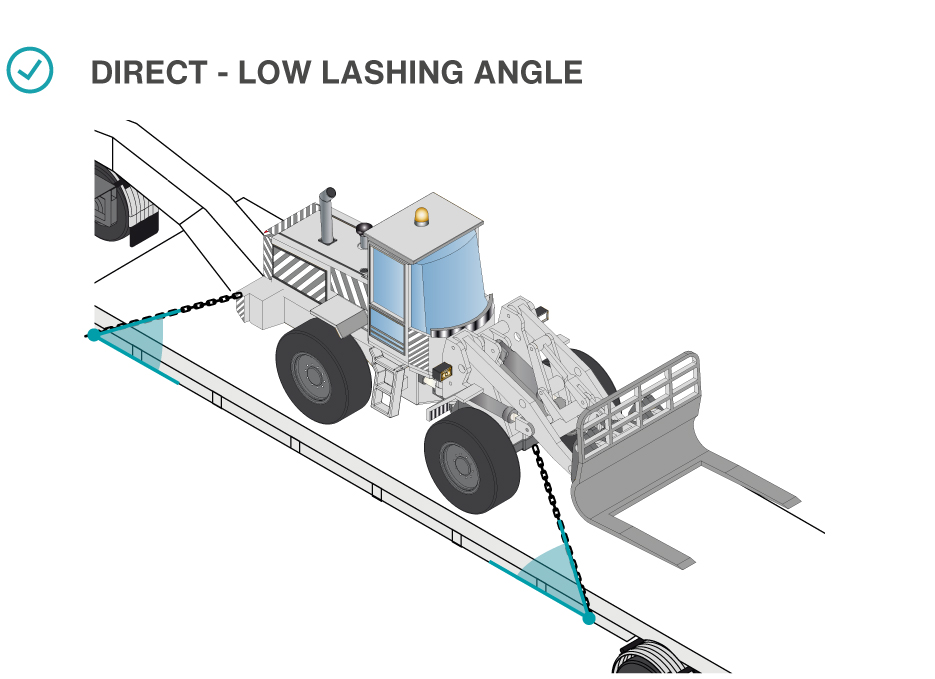

With direct restraint the steeper the lashing angles the less effective the lashing becomes.

Lowering the lashing angle increases the effectiveness of the lashing.

Risks

Good practice

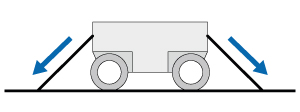

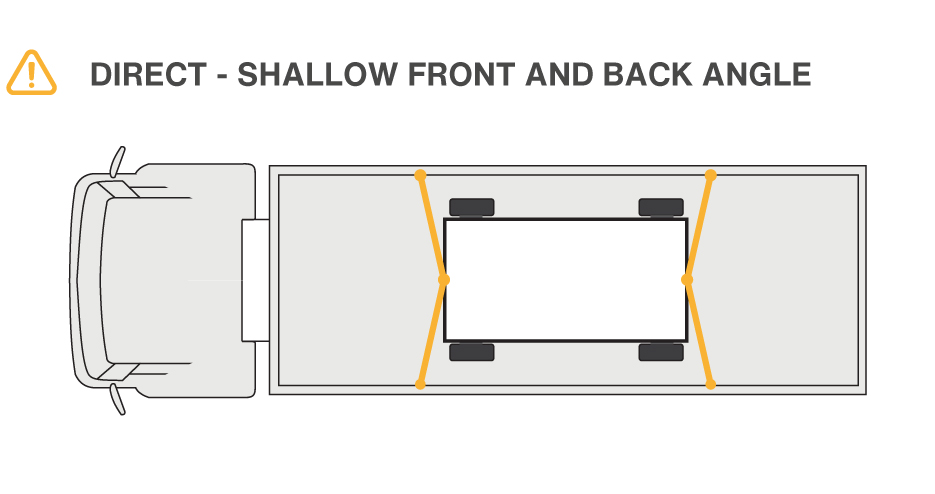

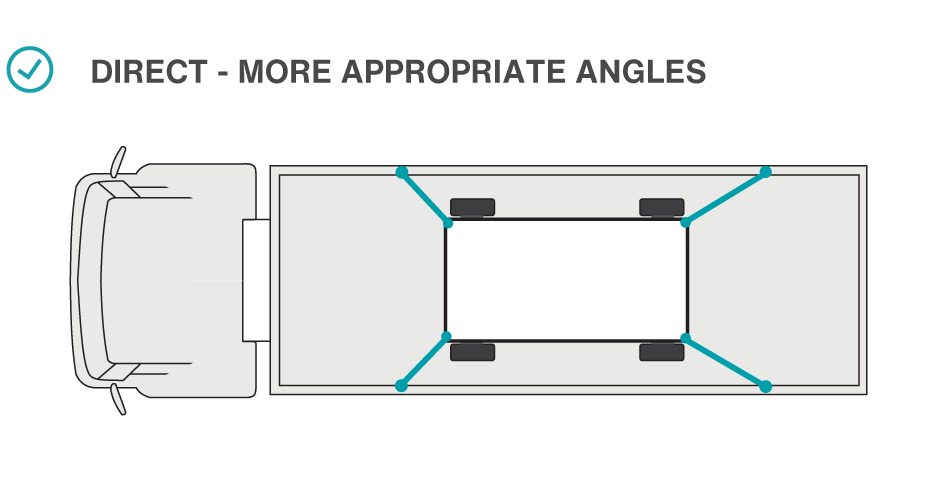

Shallow lashing angles provide less forward and backward restraint.

Increasing the lashing angle improves the ability of the restraint system to control forwards, sideways and backwards movement.

Risks

Good practice

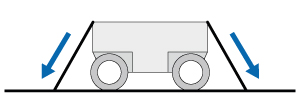

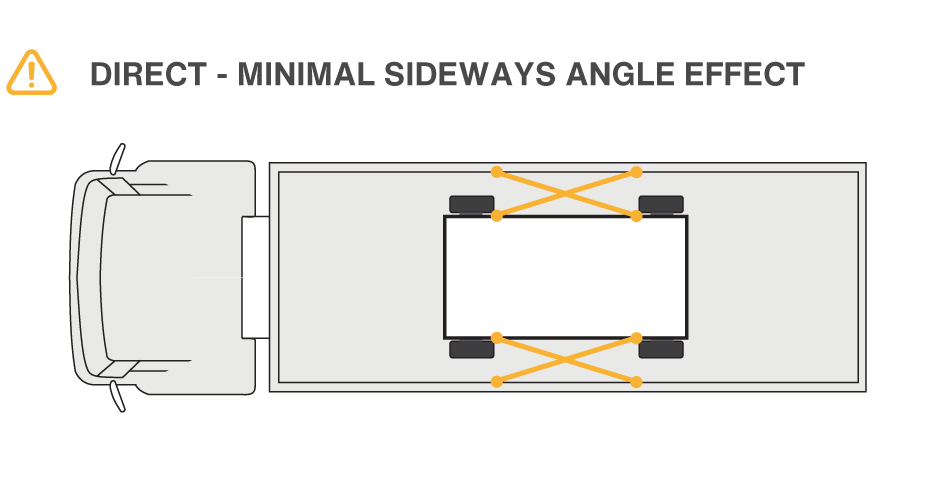

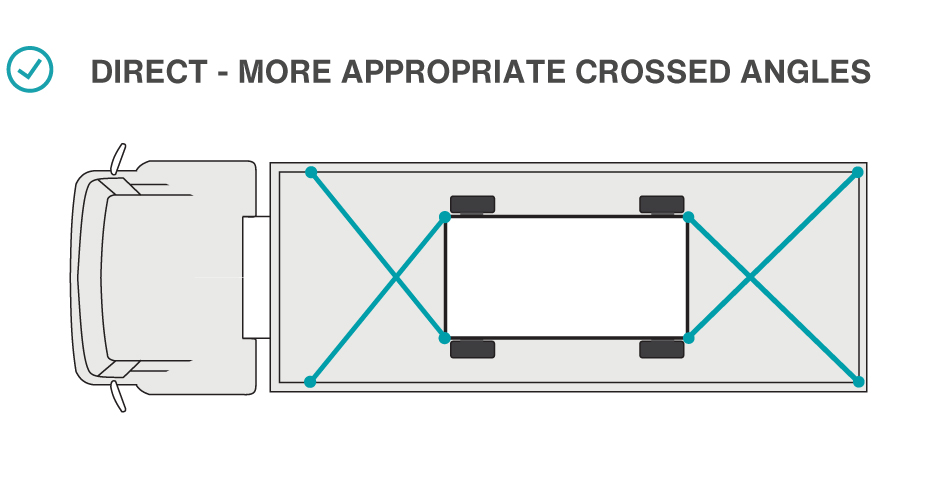

Narrow side angle lashings provide less sideway restraint. Crossing over lashings provides the best of both worlds or in this case all directions.

Risks

Good practice

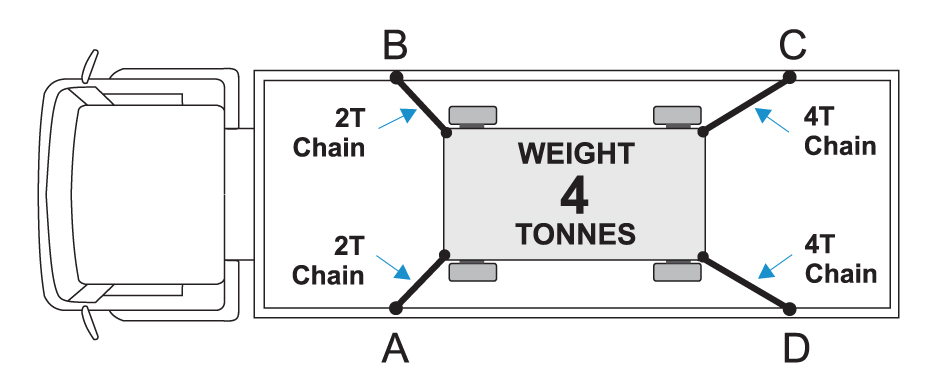

Case study

A heavy low loader combination loaded with a 25-tonne excavator.

If this excavator shifts during transport, it can cause serious vehicle instability.

If it falls off, it could cause serious injury or death to other road users and substantial damage to road infrastructure. It would also be very costly to recover and reload on another vehicle.

The restraint system is comprised of four turnbuckle ratchets with 10mm chain. The extra chain you can see in the photo was restraining the smaller bucket inside the main bucket.

The excavators steel tracks are sitting directly on the steel deck of the trailer resulting in very low friction, so the direct restraint system needs to do most of the grunt work.

The angles of the four chains do not provide sufficient restraint and fail to meet the loading requirements. In particular the angle of the restraints does very little to prevent sideways movement.

Always contact manufacturers to see if they have loading plans for their equipment. These plans will identify the attachment points that are strong enough to restrain the load. Guessing the strength of the attachment points or the restraint method is extremely dangerous.

This excavator had internal attachment points where lashings could have been attached and angled across the trailer to provide additional sideways restraint.

Seek professional advice from suitably qualified engineers if you are in any doubt as to how to restrain this type of equipment to meet the loading requirements and loading performance standards set out in the Heavy Vehicle National Law.

Accessibility tools

Accessibility tools