Loading Guide - Hay

Loading Guide - Hay

National

Heavy

Vehicle

Regulator

This guide is part of a series of loading guides that provide tips and tricks to help you understand good load restraint. More detailed information on the principles covered by this guide can be found in the Load Restraint Guide 2025.

What is hay?

Hay is grass, legumes, or other herbaceous plants that have been cut and dried to be stored for use as animal fodder.

For the purposes of this loading guide ‘hay’ also includes straw and silage.

These products are usually gathered and stored in a bale, which is tightly bound with twine, netting or plastic.

Bales may be square, rectangular, or round, and can be very large, depending on the type of baler used.

| Bale type | Approximate mass (kg) |

|---|---|

| '3'x3' | 360 |

| 8'x4'x3' | 570 |

| 8'x4'x4' | 760 |

| Round 4'x4' | 350 |

| Round 5'x4' | 500 |

| Note: The weight of a bale can vary greatly depending on the fodder type and baling machinery, i.e. denser packing. | |

Key risk factors to look for when transporting hay

- Bale condition - Lower bale density can increase sagging.

- Baling process - Poor quality baling methods can deliver inconsistent bale density, shape and size.

- Bale compression - The tighter the bale is compressed will affect the bale density and weight.

- Bale size and shape - The size and shape of the bale will also impact the weight of the bale. For example, a round bale is generally more tightly compressed and will weigh more than a square bale.

- Bale age - Older bales can lose shape, and wrapping can deteriorate from UV and rodent exposure.

- Bale moisture content - If the hay has been baled with higher moisture content, or the bale has been affected by rain, the weight of the bale may be increased.

- Centre of gravity - Higher centre of gravity increases vehicle instability.

- Height to width ratio - When the load height is significantly greater than width, it is less stable and more likely to shift.

- Vehicle movement and forces - Braking, acceleration, corners, and uneven road surfaces can all increase the risk of load shifting.

- Loading - Uneven weight distribution, and use of inappropriate restraint equipment or equipment with excessive wear can impact the loads stability.

- Fire - Vertical vehicle exhausts fitted behind the cab and shorter than the load height, can increase the potential for combustion.

How to prevent load shifting

Poorly loaded or inadequately restrained loads can cause hay bales to dislodge or fall, posing a significant safety risk to workers and other road users.

Keep loads low, long and wide

- Stack round bales flat side down to prevent bale movement.

- Rounds bales carried on their flat side may be more stable.*

- Stack square bales wide side down to prevent toppling.

- Square bales can have a hard and soft side, and a hard and soft end, i.e. on a 4x4 bale the soft side is where the knots are, they should be loaded on their side with strings facing out, and knots facing to the middle. The hard end of bales should face to the rear of trailer.*

Use blocking

- Block items against a vehicle structure i.e. headboards and gates or other freight to reduce movement and prevent tipping.

Secure the load

- Fully tension lashings and check them regularly when using tie-down restraint as loads may settle.

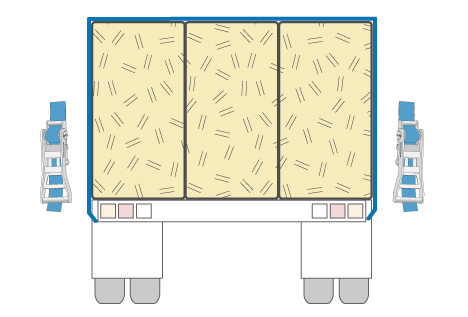

- Use a minimum of 50mm wide straps rated to 2.5 tonne with pull-down ratchet binders.*

- Multiple lashings may be needed to secure each row in the stack.

Drive with care

Take wider and slower turns and maintain steady acceleration and braking to minimise sudden movements that could destabilise.

Restraint methods

Direct restraint

Containment

Using structures such as load rated curtains, gates, headboards.

Blocking

Restraining bales using vehicle structures such as headboards, tail gates and ramps where fitted.

Tie-down Restraint

Single lashing

A single lashing hooked on to the tie rail on one side of the deck, passed over the load and tightened on the other side by a tensioner.

Double tensioned - single lashing

A single lashing with a tensioner on each side.

Double lashings

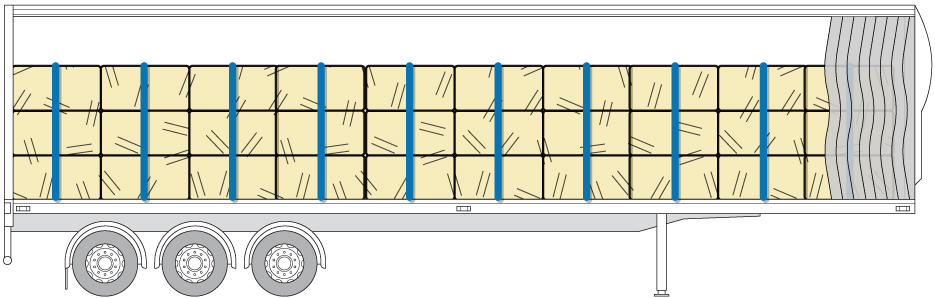

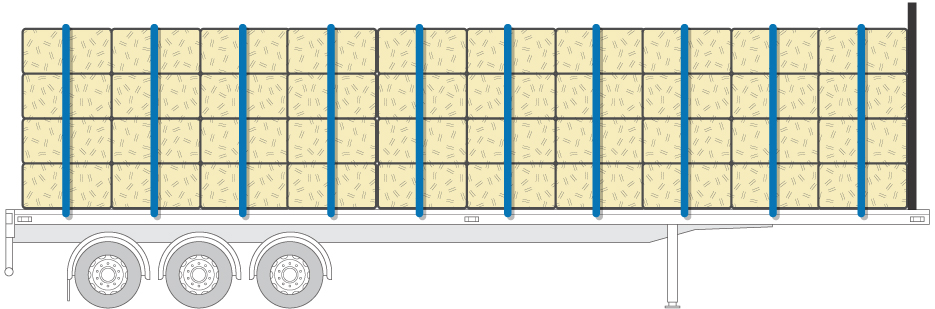

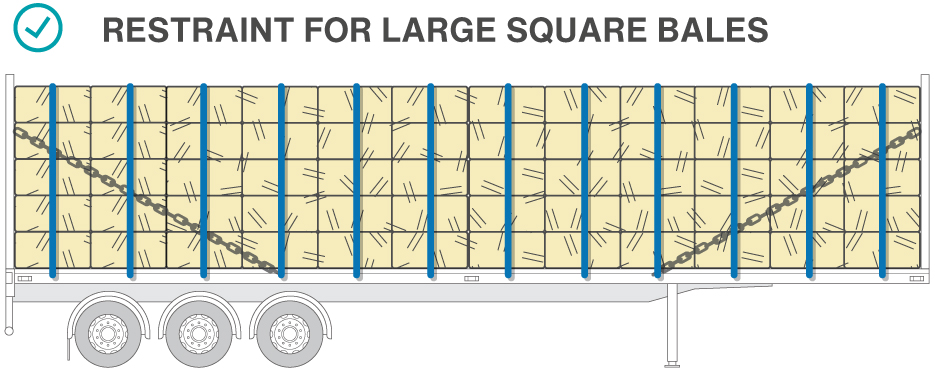

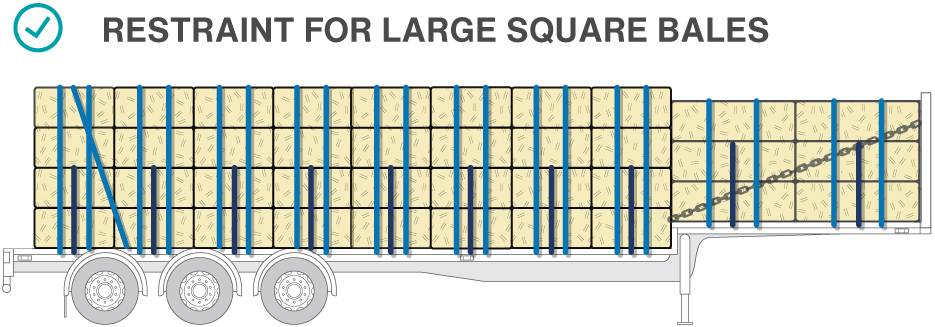

Two single lashings per block of bales. This method is more suitable for large square bales than round bales.

Half high lashing (belly lashing)

Double lashings with an additional half high lashing over the lower half of the load.

Note: Advice on this page applies to well-constructed bales and loads. Apply more restraints for soft and poorly baled loads.

Useful tips for load restraint

- The tensioner side of the lashings should be alternated to provide even restraint on both sides of the load.

- Applying additional half high lashings, over the lower half of the load, improves restraint stability particularly for high loads.

- Double tensioned - single lashing is particularly useful near the centre of the trailer deck, poorly formed bales and for restraining round bales.

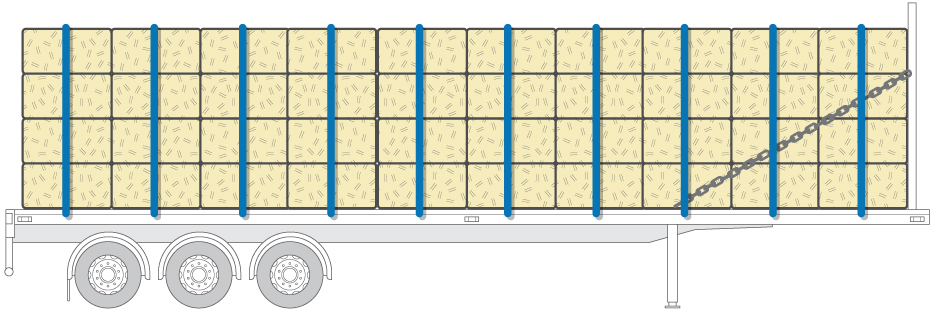

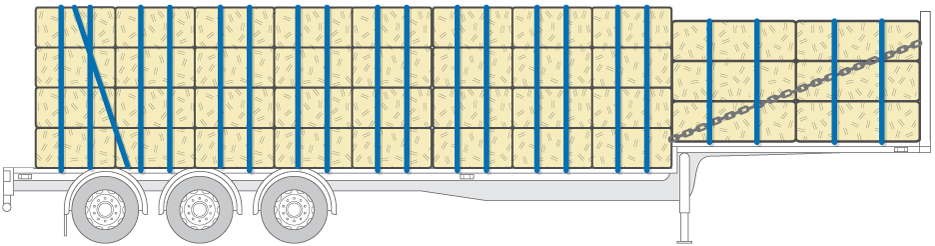

- Diagonal bracing lashings are recommended to improve load stability, particularly for the front and rear groups of bales on a trailer, with the bracing pulling towards the centre of the trailer.

- Always consider the use of headboards and tail gate to assist with restraint.

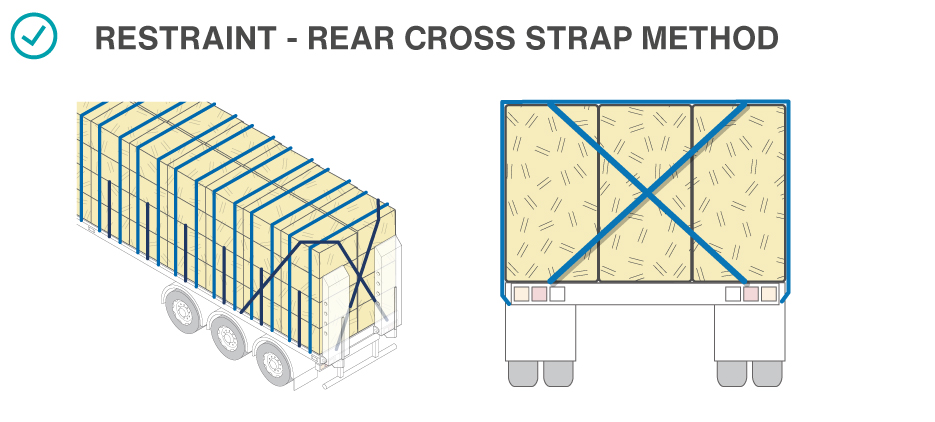

Rear Restraint - Cross strap method

Two webbing straps, each crossed diagonally from the rear of the trailer, over the load’s corners, and down to the vehicle’s deck on the opposing side.

This technique creates an ‘X’ to provide load stability and minimise shifting during transportation.

This method increases the effectiveness of the load restraint system, especially for unblocked loads.

Depending on composition of bales, the cross-strap method can slip off. If this is the case, use the diagonal strapping method.*

*Indicates information provided by industry feedback and is not verified.

Resources

For further advice on the load restraint refer to our loading page, contact your association or contact a qualified load restraint engineer.

Accessibility tools

Accessibility tools