Regulatory Advice - WHS and CoR

Regulatory Advice - WHS and CoR

National

Heavy

Vehicle

Regulator

Note: This information is intended to provide general guidance only and does not constitute legal advice. We encourage you to obtain independent advice about your legal obligations. If you have any feedback on the information provided please contact us at info@nhvr.gov.au

This regulatory advice highlights the similarities and differences between the Heavy Vehicle National Law (HVNL) primary duty, and the Work Health & Safety (WHS) primary duty of care. It provides guidance to parties in the heavy vehicle Chain of Responsibility (CoR) on opportunities where existing WHS risk management strategies can be developed and expanded to include public risks that arise from the use of heavy vehicles on the road.

Who is this advice for?

- Parties in the Chain of Responsibility (CoR parties).

The primary duty

This is an obligation to eliminate public risks, or to the extent it is not reasonably practicable to eliminate risks, to minimise public risks. It also includes a prohibition against directly or indirectly causing or encouraging a driver or another person, including a party in the CoR, to contravene the HVNL. CoR parties should be aware that they remain a CoR party even when their transport activities are contracted, or subcontracted, to another party.

Note: Transport activities include all activities and business processes associated with the use of a heavy vehicle on a road.

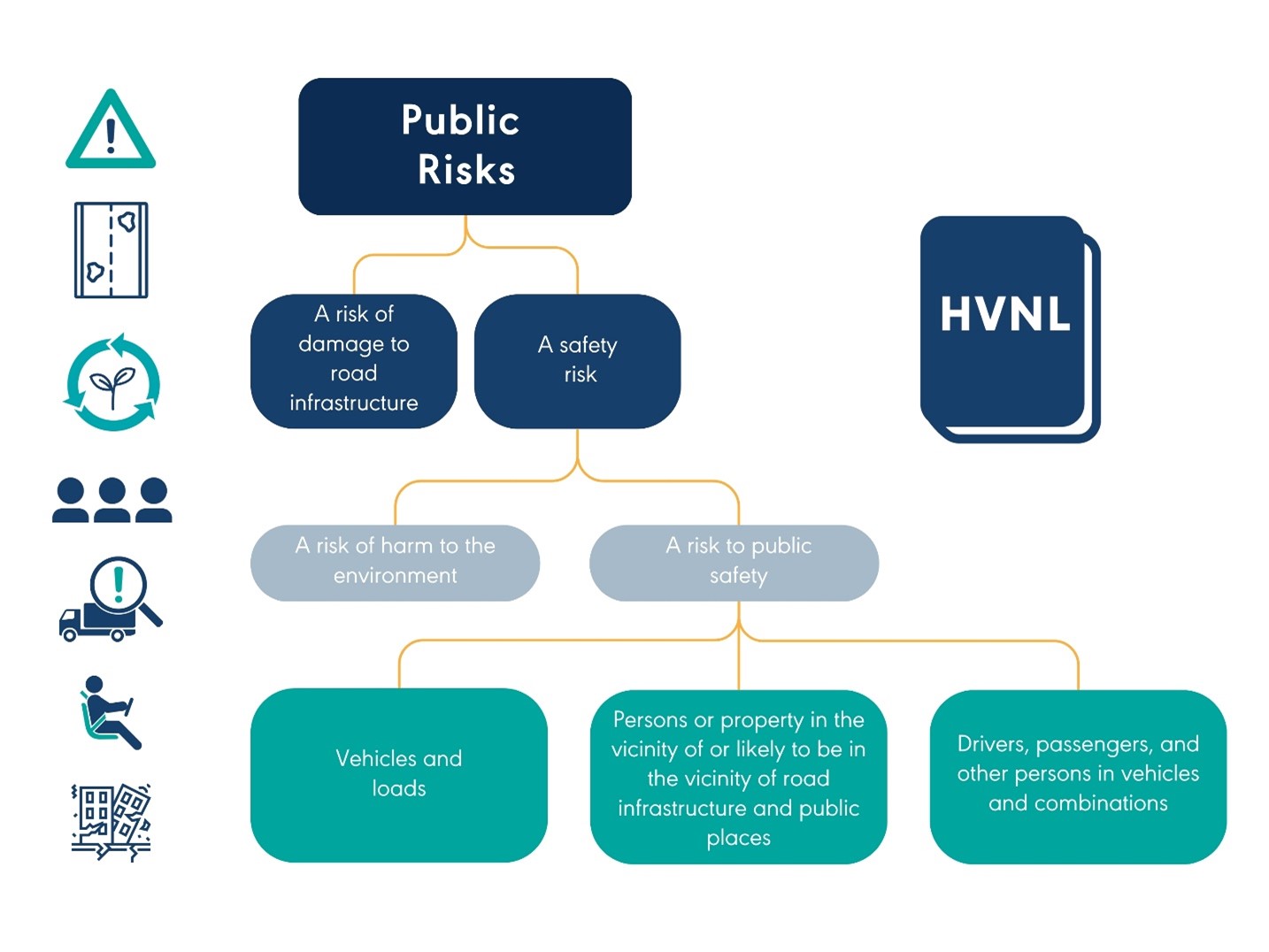

What are public risks?

The HVNL defines public risks in broad terms. The intention is to ensure public safety when a heavy vehicle is used on a road. Section 5 of the HVNL outlines public risks to include risks to the safety of:

- drivers

- passengers and other persons in vehicles

- people or property in the vicinity of road infrastructure or public places

- vehicles and loads

- damage to road infrastructure

- harm to the environment

HVNL primary duty and WHS primary duty of care

Compliance with the HVNL primary duty can be approached in the same way as the primary duty of care under WHS law and other duty-based laws. The standard is the same, to do what is reasonably practicable, and both are about proactive prevention of harm by eliminating or minimising risks. This is because the HVNL adopts and adapts concepts from WHS law and applies those concepts to parties in the CoR. Many CoR parties are also duty holders under WHS laws and should already be familiar with WHS principles and terminology. The overarching object of both duties is to ensure safety and eliminate or minimise risk, and both duties emphasise that ensuring safety is a shared responsibility between parties. However, there are some differences between the two frameworks and compliance with WHS law does not necessarily mean that HVNL primary duty obligations are met.

Key Similarities

- Application of a general duty, rather than prescriptive requirements

- Legal entity has the duty

- Focus is upon safety outcomes

- Concept and definition of so far as is reasonably practicable

- Duty to eliminate or minimise risk so far as is reasonably practicable

- Distinct personal duty of officers/executives

- Principles about duties and shared responsibility

- Codes of practice provide more detailed recommendations

- Similar penalty orders

Key Differences

The main difference between the two duties is their object. WHS primary duty of care is concerned with the health and safety of workers and others in a workplace. The HVNL primary duty is concerned with public risks when a heavy vehicle is used on a road.

Purpose and Scope |

|

|---|---|

| HVNL Primary Duty: Aims to eliminate or minimise public risk when a heavy vehicle is used on a road. | WHS Primary Duty: Focuses on ensuring the health, safety, and welfare of workers and others (e.g., contractors, volunteers, visitors) in the workplace. |

Who Holds the Duty |

|

| HVNL Primary Duty: The duty applies to all parties in the Chain of Responsibility. | WHS Primary Duty: The duty is placed on the Person Conducting a Business or Undertaking (PCBU) with additional duties placed on workers. |

Due Diligence Obligations |

|

| HVNL Primary Duty: Requires executives of entities that are CoR parties to exercise due diligence to ensure their business complies with its primary duty. | WHS Primary Duty: Requires officers of the business to exercise due diligence to ensure the PCBU complies with its duties. |

Note: HVNL section 18 outlines the relationship of the HVNL with primary work health and safety laws including that both laws should be complied with, but where it is not possible to comply with both provisions, the provision of the WHS Law will prevail. For example, when compliance with the HVNL would create disproportionate WHS hazards and risks.

Do I have to do more to comply with the HVNL primary duty than the WHS primary duty of care?

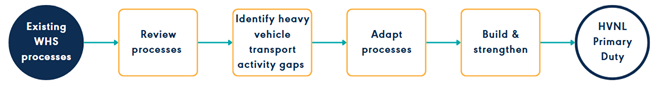

A lot of the work you currently do, and your existing skills and knowledge used to manage safety at your workplace as part of your WHS responsibilities will contribute significantly to complying with the HVNL primary duty. However, the focus of your risk management may be different.

For businesses that operate heavy vehicles and/or employ drivers, there may be a substantial overlap between, and many existing control measures will help you comply with both duties.

The challenge is that a PCBU can apply a high level of influence over what happens at a workplace, but a CoR party might perform their transport tasks across long distances, over multiple days, and across multiple locations.

Parties in the CoR must take additional proactive steps to ensure safety and manage public risks across all parts of the heavy vehicle journey, including beyond their premises. You may need to build upon your WHS risk management processes to manage hazards and risks to the public associated with the use of a heavy vehicle on a road.

Shared responsibility under the HVNL

This means that each CoR party shares responsibility and has the same duty to ensure safety so far as is reasonably practicable. However, each party will need to do different things and contribute to safety in different ways, and what is reasonably practicable may be different from party to party. The foundation of the CoR principle recognises the connection between CoR parties and their activities across the supply chain. No party, on road or off road, acts in isolation.

The unique part of shared responsibility under the HVNL primary duty is that your duty doesn’t end just because a heavy vehicle has departed your premises or you have completed your part of the transport task. The duty continues until the vehicle has completed its journey and all associated public risks have been eliminated or minimised. However, in practice your visibility of any emerging hazards and risks may diminish as the journey progresses.

This is why the sharing of information is essential to ensure all parties can effectively work together to manage hazards and risks associated with the heavy vehicle journey. Communication between parties allows a considered approach to understand how controls have been implemented across the supply chain. This also allows clarity around which party is doing what, and promotes each carrying out their duty according to their capacity to eliminate, or minimise risk. CoR parties need to share the right information, at the right time, with the right people:

- before the journey – to plan and optimise safety, communication, and efficiency

- during the journey – exchange updates to respond to changing conditions

- after the journey – review and share insights to improve practices.

For example, if your transport activities include packaging and unitising goods for transport and throughout the journey the packaging fails because of something you did or didn’t do you could be liable.

Note: Where multiple parties have a primary duty for the same activity, the primary duty does not change. Regardless of how many parties there are, the duty and level of responsibility remain the same. More information on shared responsibility under the HVNL can be found in Regulatory Advice – The Primary Duty.

How can I use my existing WHS risk management strategies to manage heavy vehicle risks?

Building on existing policies

All public risks that arise from the use of a heavy vehicle on the road must be managed. Existing risk management policies and procedures may cover a range of risks, some of which are relevant to heavy vehicle operations including: safety policies, alcohol and drug policies, and training policies.

Where public risks that arise from the use of a heavy vehicle are not sufficiently controlled, existing policies and procedures will need to be reviewed and updated. The risk management process will remain the same, however the focus will broaden to incorporate risks to public safety.

Chain of Responsibility Policy

The Chain of Responsibility Policy should establish the business’ intention to carry out all activities associated with the use of a heavy vehicle on a road with public safety and risk management at front of mind. Documentation should describe the overarching purpose, establishing the business as the party in the HVNL Chain of Responsibility and confirm that the business is accepting responsibility as a primary duty holder. It should highlight CoR functions carried out as part of business operations and detail all the heavy vehicle transport activities the business performs.

Work Procedures

Work procedures should be developed to prescribe how transport activities will be carried out at an operational level. These work procedures should form part of the business’ risk management strategy and prioritise driver, other worker, and public safety. Work procedures may include:

- Induction/training

- Communication and Consultation

- Heavy Vehicle Driver Fatigue Risk Management

- Safe Driving

- Fitness to drive/work

- Alcohol and other drugs

- Loading and Unloading

- Mass and Dimension

- Vehicle Inspection, Fault Reporting and Maintenance

Case studies WHS vs HVNL

Focussing on different risks: Loading a heavy vehicle

When loading a heavy vehicle, WHS would prioritise the immediate safety of workers loading goods, and workers and others in the vicinity.

WHS would consider hazards such as:

- people falling from heights when loading a heavy vehicle

- use of equipment including if it is fit for purpose and well maintained

- worker training on use of equipment

- people struck by forklifts, or other vehicles

- falling objects during loading

- hazardous manual tasks

- proper handling of dangerous goods.

Under the HVNL primary duty the focus is on potential public risks after a loaded heavy vehicle leaves your premises. This means ensuring the load is properly planned, the packaging and unitising method is appropriate, the load is positioned and distributed correctly on the vehicle and the load restraint system complies with the HVNL loading requirements and meets the loading performance standards.

HVNL primary duty would consider hazards such as:

- objects becoming dislodged and falling from vehicles

- dislodged objects hitting other vehicles or drivers having to swerve to avoid fallen objects

- load shifting causing the vehicle to become unstable or to roll over

- load spillage – bulk commodities, liquids

- the load impacting the cabin when braking

- packaging failures making loading or unloading hazardous

- load configuration for multiple drop offs impacting on continued load restraint effectiveness, vehicle stability, and load distribution throughout the journey.

Implementing additional controls: Fitness to work

This is an example of building upon existing WHS risk management framework to control the additional hazards and risks associated with the use of a heavy vehicle on a road, ensure safety, and meet your primary duty as a CoR party.

Under both WHS and HVNL fitness to work of workers and/or drivers is a hazard that could result in harm if appropriate controls are not implemented to manage the risk. Whilst many of the controls used to determine fitness to work for employees in the workplace may be effective, to ensure the safety and eliminate or minimise public risk for the entire heavy vehicle journey, additional controls may need to be implemented.

For example, when assessing fitness to work of an onsite worker a supervisor can undertake informal assessments throughout the shift to observe any visual or verbal cues that may indicate that a person is unfit to work. Where a person does show signs they are unfit to work, immediate action should be taken to remove them from their assigned tasks, eliminating the associated risks.

However, it is much harder to assess heavy vehicle drivers as they are often working alone and may not be in offices or depots at the same time as supervisors, if at all. Therefore, additional controls may need to be implemented to ensure driver fitness such as:

- Detailed medical assessments to identify any pre-existing conditions.

- Welfare checks throughout shifts, empowering drivers to self-declare when they are not fit for work – without penalty.

- The use of Fatigue and Distraction Detection Technology.

- Having agreed communication strategies with third parties in relation to driver behaviour.

- Isolated or lone worker procedures to facilitate the monitoring of drivers in the ways listed above.

More information on managing risks associated with fitness to work can be found here: Regulatory Advice – Fitness to work.

Building upon existing policies and procedures: Incorporating transport risks into site inspections

Undertaking regular work site inspections is a crucial part of managing WHS risks. Site inspections assist in identifying hazards and risks and allow you to assess and implement suitable controls to eliminate or minimise risks and reduce the potential for injury or harm.

To incorporate your transport risks into an existing WHS inspection checklist consider adding the following:

Site access and traffic management

- Designated heavy vehicle entry and exit points that are clearly sign posted so drivers can quickly and easily find where they need to go preventing delays and confusion.

- Traffic control measures such as cones, barriers or spotters.

- Managing arrival times to eliminate vehicle queuing.

Vehicle and equipment safety

- Procurement processes to include vehicle selection to ensure the correct heavy vehicle for the transport task.

- Comprehensive vehicle maintenance strategy: including scheduled and ad-hoc maintenance, fault reporting and maintenance record keeping.

- Pre-start checks.

- Load restraint systems and equipment (is equipment appropriate, has it been inspected and maintained according to manufacturer’s requirements).

- Safe parking and reversing protocols and designated heavy vehicle parking bays/ driver rest areas.

Work Environment Conditions

- Surface suitability – level areas for loading and unloading, gravel, bitumen, wet areas.

- Weather protection from wind, rain, sun or heat.

- Lighting and security for pre-dawn or night work.

- Driver amenities.

Heavy vehicle safety

- Developing loading plans.

- Trip/journey plans.

- Rostering and consigning to consider the risk of driver and other worker fatigue.

- Maintaining open lines of communication between parties in the supply chain.

- Conducting risk assessments for newly identified heavy vehicle hazards and implementing appropriate control measures.

Comparing controls: relevance to WHS Primary Duty of Care vs HVNL Primary Duty

| Control measure | WHS duty | HVNL duty |

|---|---|---|

| Managing driver health | Part of the object of the duty. | - |

| Fit and healthy driver is a safer driver, less likely to crash and harm self and passengers. | Fit and healthy driver is less likely to crash and harm self, passengers or other road users and road infrastructure. | |

| Safe packaging and unitisation of goods. | Reduces risk of injury to workers stacking or moving freight in a warehouse. | Reduces the risk that: a load disintegrates, protrudes from or falls from the vehicle, distracts driver, or affects vehicle handling, with potential of harm to driver, passengers, other road users and road infrastructure. |

| Training employees in safe animal handling. (Calm animals travel better and are less likely to fall or injure themselves during the journey.) |

Minimises the risk of a worker being injured by an animal during loading or unloading. | - |

| Minimises the risk that a driver will have to stop and climb into a trailer to attend to a fallen animal and sustain an injury. | Minimises the risk that a driver will have to stop and climb into a trailer to attend to a fallen animal which may delay the journey, thereby increasing the risk of the driver being impaired by fatigue and a hazard to himself and other road users. | |

| Installing a deck or bay at a loading facility so that drivers can safely climb up to inspect a load at level. | Minimises the risk of a fall from height by the driver. | - |

| - | Driver is better able to apply or inspect load restraint, minimising the risk that a load will fall from the vehicle and endanger the public. | |

| Installing weighbridge at loading premises | - | Reduces the risk of overloading and damage to road infrastructure. |

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT

Accessibility tools

Accessibility tools