Victoria High Productivity Livestock Vehicle (HPLV) Pre-Approved Permit-Based Scheme

Victoria High Productivity Livestock Vehicle (HPLV) Pre-Approved Permit-Based Scheme

National

Heavy

Vehicle

Regulator

What is the High Productivity Livestock Vehicle (HPLV) Pre-Approved Permit-Based Scheme?

Victoria has introduced the High Productivity Livestock Vehicle (HPLV) Scheme to assist the livestock carrier industry in attaining a higher level of productivity. HPLVs are Class 3 heavy vehicle combinations that exceed 26 metres that are designed to move livestock and fall outside the Performance-Based Standards scheme that applies to High Productivity Freight Vehicles (HPFV).

This information is intended to equip livestock heavy vehicle operators with the information they need to operate an HPLV in Victoria. Enquiries can be directed to heavyvehicles@transport.vic.gov.au.

Enquiries relating to the HPLV Accreditation can go through the following channels:

Website: Livestock and Rural Transporter’s Association of Victoria (LRTAV)

Email enquiries: accreditation@lrtav.com.au

General enquiries office@lrtav.com.au

Ph: 0400933713

Detailed information regarding accreditation requirements, business rules, facility registration forms, operator application forms, auditors’ information and network maps can be found at HPLV Accreditation Scheme.

Key requirements to operate an HPLV

HPLVs must:

- Only travel under a Class 3 permit issued via

.

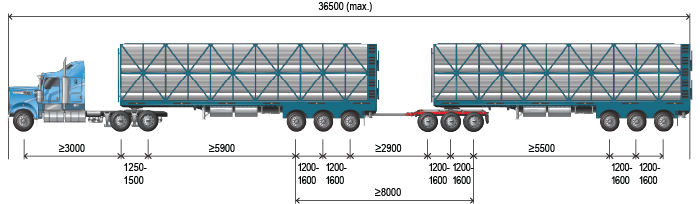

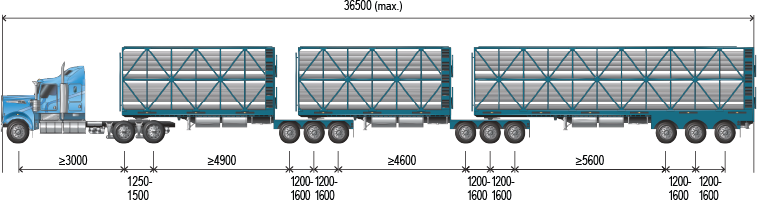

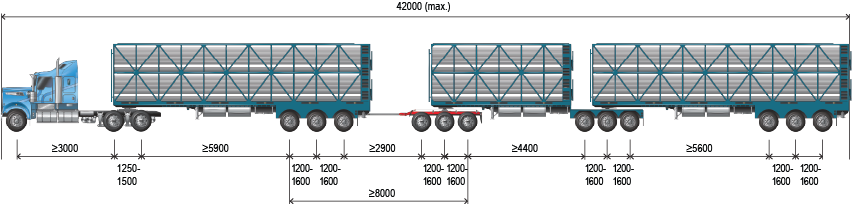

. - Match one of the reference vehicle designs specified in 'Reference vehicle designs and axle spacings'.

- Be enrolled in the HPLV Accreditation through the LRTAV.

- Report all near miss* incidents to the LRTAV.

- Comply with the Payload Management Procedure where required.

- Meet the mass and dimension limits specified in this HPLV Scheme.

- Comply with the Prevention of Cruelty to Animals Act 1986 and the Code of Practice for the Welfare of Farm Animals During Transportation, January 2002. This requires compliance with penning density requirements of the Victorian Livestock Loading Scheme (VLLS)

- Be fitted with an in-vehicle GPS device accredited under the Telematics Monitoring Application (TMA) or Road Infrastructure Management (RIM)

- Be fitted with Load Proportioning Valves (LPVs) or an Anti-lock Braking System (ABS) on all axles (excluding converter dolly axles) in line with 'Compliant braking systems and Directional Stability Under Braking (DSUB) transitional arrangements'.

- Be fitted with road-friendly suspension in line with Vehicle Standards Bulletin 11.

- Be compliant with ADR 80/02 (Euro 4) emissions.

- Have a minimum rated engine power of 410 kilowatts (550 horsepower).

*Note: Near miss is defined as any occurrence that might have led to injury or illness to people, danger to health and/or damage to property or the environment.

Reference vehicle designs and axle spacings

Please note that all measurements for reference vehicles in Figures 1 to 3 are in millimetres.

Compliant braking systems and Directional Stability Under Braking (DSUB) transitional arrangements

HPLVs can use any current PBS-compliant braking system, including Load Proportioning Valves (LPV) or Anti-lock Braking Systems (ABS).

In light of upcoming changes to the DSUB standard of PBS compliant braking systems, transition to the new standard will be mandatory. On 1 July 2026, compliance with the following DSUB requirements will become mandatory for new vehicles entered into the scheme:

The hauling unit/s (including rigid vehicles):

- must be fitted with ABS that meets the performance requirements of the ADR 35/04 or later; and

- if capable of towing a trailer the hauling unit must supply an electric control signal complying with ISO 11992-2.

Trailing unit/s (including dollies):

- must comply with the latest version of ADR 38 in force at time of PBS certification; and

- must be fitted with TEBS with an ABS function enabled that meets performance requirements of the latest ADR 38 in force at time of PBS certification; and

- If capable of towing a trailer must be fitted with wiring between electrical connections to ensure all advanced braking systems are able to operate correctly; and

- installed TEBS must be fitted with an appropriate means of indicating the status of the advanced braking system.

All combination vehicle/s:

- must have a functioning EBS wiring network to support CAN communications across the entire combination, with adequate power to maintain functionality of the Trailer Electronic Braking System (TEBS) of all trailers and dollies in the combination.

Mass and dimension limits

Maximum Dimensions

The maximum dimensions for HPLVs are detailed in Table 1.

| Network | Height (m) | Width (m) | Length (m) |

|---|---|---|---|

| HPLV Tri A-double | 4.6 | 2.5 | 36.5 |

| HPLV B-triple | 4.6 | 2.5 | 36.5 |

| HPLV AB-triple | 4.6 | 2.5 | 42.0 |

Axle group mass limits

Axle group mass limits for HPLVs are permitted to exceed general mass limits (GML) up to specific mass limits. Table 2 details the maximum axle group mass limits for HPLVs.

| Axle configuration | Axle group mass limit (t) |

|---|---|

| Steer axle | 6.0 |

| Steer axle* | 6.5 |

| Steer axle* | 7.1 |

| Tandem axle group | 17.0 |

| Tri-axle group | 22.5 |

| *Provided the prime mover complies with the requirements set out in Schedule 1 of the Heavy Vehicle (Mass, Dimension and Loading) National Regulations (MDL). | |

Gross combination mass limits

In addition to load limits for each axle group, an HPLV must not exceed gross combination mass (GCM) limits. These limits are detailed in Table 3.

| Network | GCM (t) |

|---|---|

| HPLV tri-dolly A-double | 91.6 |

| HPLV B-triple | 91.6 |

| HPLV AB-triple | 114.1 |

Payload Management Procedure

For some livestock, A-doubles and AB-triples operating as HPLVs will need to adhere to the Payload Management Procedure to mitigate rollover risk. The trailers, livestock type and mean live weight thresholds are detailed in Table 4.

| Combination trailer | Livestock type | Mean live weight (kg) |

|---|---|---|

| A-double and AB-triple - Front trailer | Cattle | 500 |

| Sheep and goats | 40 | |

| Pigs | 150 | |

| A-double - Rear trailer | Sheep and goats | 50 |

Where possible, operators must load livestock in a way that does not exceed the mean live weight thresholds specified for trailers listed in Table 4.

Where a payload cannot be kept under the relevant mean live weight thresholds in Table 4, or where the mean live weights are not known, the Payload Management Procedure must be adhered to.

When the payload management procedure is required, a listed trailer to be loaded with livestock that exceed the mean live weights in Table 4 is considered a payload managed trailer.

Under the Payload Management Procedure, the operator must:

- load larger livestock onto non-payload managed trailers and the bottom deck of payload managed trailers;

- load smaller livestock on the top deck of payload managed trailers;

- load as few livestock on the top deck of payload managed trailers as possible; and

- plan the journey with due consideration to safety in terms of stability in line with mandatory operator training.

Further requirements

TMA or RIM

TMA and RIM are certified vehicle-tracking systems using telematics to collect road use data with the aim to better inform and optimise the management of road networks.

Both TMA and RIM use tamper-evident GPS devices installed in the vehicle connected wirelessly to accredited third-party service providers.

Unless otherwise approved, operators must provide road use data by participating in TMA or RIM using a certified in-vehicle unit.

Further information about the TMA and RIM is available on the TCA website.

Minimum tyre ratings

Minimum tyre ratings on axles must be adhered to and are specified in Table 5. The rated load of individual tyres is not to be exceeded.

| Tyre | Minimum load index | Rated load (kg) |

|---|---|---|

| Steer axle up to 6.5t | 149 | 3250 |

| Steer axle up to 7.1t | 152 | 3550 |

| Drive and trailers | 144 | 2800 |

Signage

All HPLV combinations must warning signage that complies with the VSG19 - Vehicle warning signs (PDF, 547KB).

Symbols on the HPLV networks

To cater for the low-speed swept path (LSSP) width of 36.5m and 42m combinations, additional information has been added to the HPLV network maps.

Map symbols have been introduced to denote:

![]() intersections where turns do not provide LSSP access up to 10.6m.

intersections where turns do not provide LSSP access up to 10.6m.

Where can HPLVs operate?

An HPLV with a design that meets one of the reference vehicle designs detailed in this information sheet, and can only operate on the road network specific to its reference vehicle.

Victoria’s HPLV networks have been developed with a focus on primary livestock routes and destinations. AB-triples up to 42m have a more restrictive network due to their length.

The networks expand as assessments are undertaken and bridges and other structures upgraded.

The access status of each route is denoted by its colour. The HPLV networks can be viewed on the NHVR National Network Maps.

Are HPLVs required to meet Performance Based Standards (PBS)?

HPLVs are not required to have a PBS vehicle approval as long as they meet all the requirements specified to operate as an HPLV. It is acknowledged that participation in the PBS scheme is difficult for livestock vehicles due to their high payload centre of gravity. The HPLV network conditions and reference vehicles have been developed to mitigate key concerns such as rollover.

Do HPLVs require Smart On-Board Mass (Smart OBM)?

HPLVs operating under pre-approved permits are not required to have Smart OBM. A three-year transitional arrangement to a new gazette notice will introduce a requirement for HPLVs to have Smart OBM for continued access under the scheme.

What if my design doesn’t match one of the reference vehicles?

There are a number of reference vehicles with networks and assessment results for Victoria contained within the National Class 2 Performance Based Standards (High Productivity) Authorisation Notice 2024 (No.1). Operators can consider whether it is worthwhile meeting the requirements to operate as a High Productivity Freight Vehicle (HPFV) under the notice and have access to the HPFV networks.

Livestock combinations operating under the HPLV Scheme can also gain access to HPFV reference vehicle networks where they match the spacings for those vehicles.

Combinations that do not match any of the HPLV reference vehicles listed will still need to meet all other HPLV requirements and will require a bespoke payload management plan specific to the combination.

Combinations that do not match any published reference vehicle will require bridge assessments at the cost of the operator.

Shorter livestock vehicles, including 26m B-doubles and 19m prime mover semitrailers are to adhere to Victoria’s Livestock Loading Scheme, available in the Victoria Class 3 Heavy Vehicle Livestock Carrier Mass Exemption Notice 2024 (No.1).

Can existing road trains access the HPLV networks?

The HPLV networks have been introduced to enable longer livestock vehicles greater access whilst recognising the challenges these vehicles can face in meeting Performance Based Standards. Existing road trains that match one of the reference vehicles can operate on that reference vehicle’s network as long as all requirements for the HPLV networks are met.

Do I need an NHVR permit?

HPLVs require a permit to operate on the HPLV map network. A permit is required for any access requirement that is not part of the road network specified for that reference vehicle.

Do I need a permit to cross rail tracks?

Operators of HPLVs that exceed 26.0 metres in length and cross at-grade rail or tram tracks must apply for an over-dimensional load (ODL) rail permit.

Rail permits can take up to 15 business days to process.

Further information on obtaining an ODL rail permit is available on the Victorian Department of Transport and Planning website.

Will there be any changes to the HPLV Scheme?

As a brand new scheme that provides unprecedented access for longer livestock carriers, there will be annual reviews for the first five years of operation. These reviews may identify changes to ensure continued safe and efficient access for HPLVs in Victoria.

The scheme will also be subject to ongoing adjustments in collaboration with the LRTAV and through regular industry consultation.

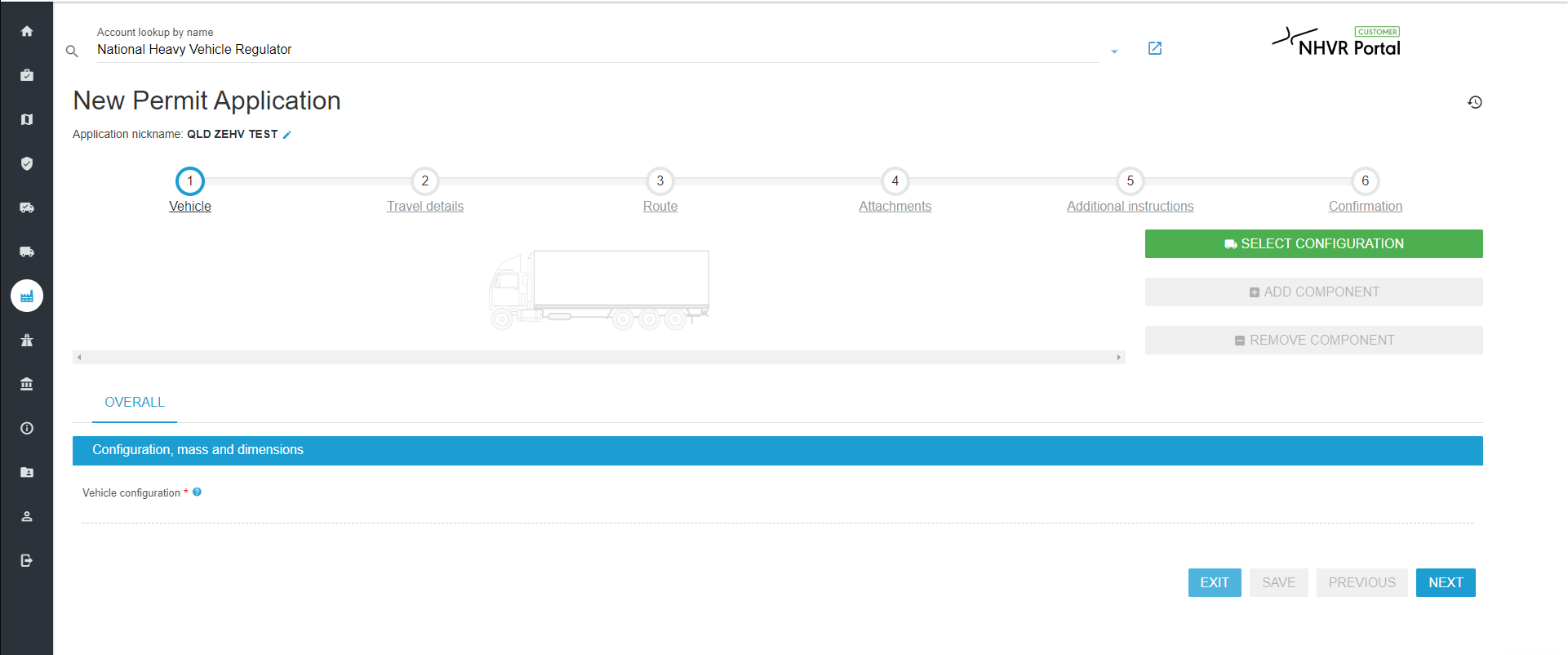

How to apply for the Victorian HPLV Scheme

To begin your permit application, navigate to  . If you are not already registered, follow the prompts to set up an account.

. If you are not already registered, follow the prompts to set up an account.

Once registered, from the home screen, click on the ‘Application tracker’ tab and select the ‘NEW APPLICATION’ button and enter a reference for your application. So we can correctly identify your application, your reference/application nickname should be 'VIC HPLV'.

Note: Where you have an existing permit for an eligible configuration, select the ‘AMEND' application button, which will require the permit number to be entered. Follow the prompts to add the additional routes required.

Step 1 - Click the green ‘SELECT CONFIGURATION’ button and select the 'VIC Permit Schemes' menu drop-down. Select one of the relevant configurations from the list:

- VIC - HPLV - A-Double

- VIC - HPLV - B-Triple

- VIC - HPLV - AB-Triple

Step 2 - Once the correct configuration is selected, click on the ‘OVERALL' tab and go to ‘Configuration, mass and dimensions.' The vehicle type will require the following vehicle details:

- laden mass limits

- height (4.3m or 4.3m-4.6m)

- length will be automatically selected to the maximum length of the combination allowable under the scheme

- 'Permit scheme' name - "Victoria High Productivity Livestock Vehicle Pre-Approved Permit Scheme".

Note: Registrations must be added for prime movers only. Trailer components just need the correct component box ticked. Trailer registrations are not required.

In the component images, you must tick the box "☐ I confirm selection of the correct component" prior to proceeding to the ‘Travel details’ section of the application.

These details are required for the road manager to assess your application.

Step 3 - In the ‘Travel details’ section, enter the requested period (the period cannot exceed three years). Input the freight being carried (livestock) under the 'Description of load'.

Step 4 - Navigate to the ‘Route’ section of the application. Select the ‘Route type' as 'Single Route' or 'Area'.

- If you do not have an existing permit for the Victorian High Productivity Livestock Vehicle (HPLV) Scheme Network, select ‘Network’ and select VIC under ‘In which jurisdiction are you seeking to operate?’.

- If you have an existing permit for the Victorian High Productivity Livestock Vehicle (HPLV) Scheme Network, select ‘Area’ application is selected and the ‘Area Road Manager’ must be selected. Refer to the Routing - Single route and area difference.

- Please note: for requesting roads off the Victorian High Productivity Livestock Vehicle (HPLV) Scheme Network, an ‘Area’ must be selected. Applications for “all roads” will not be accepted.

- Plot the route(s) required that link to the approved network.

- Select the ‘CONFIRM’ tab and add any additional information in the ‘Route notes’ section in support of your application. You must tick the box ☐ 'I confirm that the list of roads and associated route notes accurately defines my route requirements for this application' prior to proceeding to the next step of the application.

Step 5 - In the 'Attachments' section of the application, attach proof of enrolment in the HPLV Accreditation through the LRTAV, and any required supporting documents or additional information.

Step 6 - The 'Additional instructions' section allows the nomination of an approved NHVR Go member of your account (if you will not be the relevant contact for the application). Include any additional instructions required for the application.

Step 7 - In the 'Confirmation' stage ensure all details of the application have been reviewed and confirmed. The application can then be submitted with the appropriate payment.

For more information on applying for a permit, refer to the NHVR access permit applications webpage, or contact us.

Accessibility tools

Accessibility tools