Loading Guide - Blocking

Loading Guide - Blocking

National

Heavy

Vehicle

Regulator

This guide is part of a series of loading guides that provide tips and tricks to help you understand good load restraint. More detailed information on the principles covered by this guide and the use of blocking can be found on page 250 of the Load Restraint Guide 2025.

What is Blocking?

Blocking is where the vehicle body structure or another rated attachment is used to prevent a load from moving forward, rearward or sideways.

Blocking can be used as part of a tie-down or direct restraint methods.

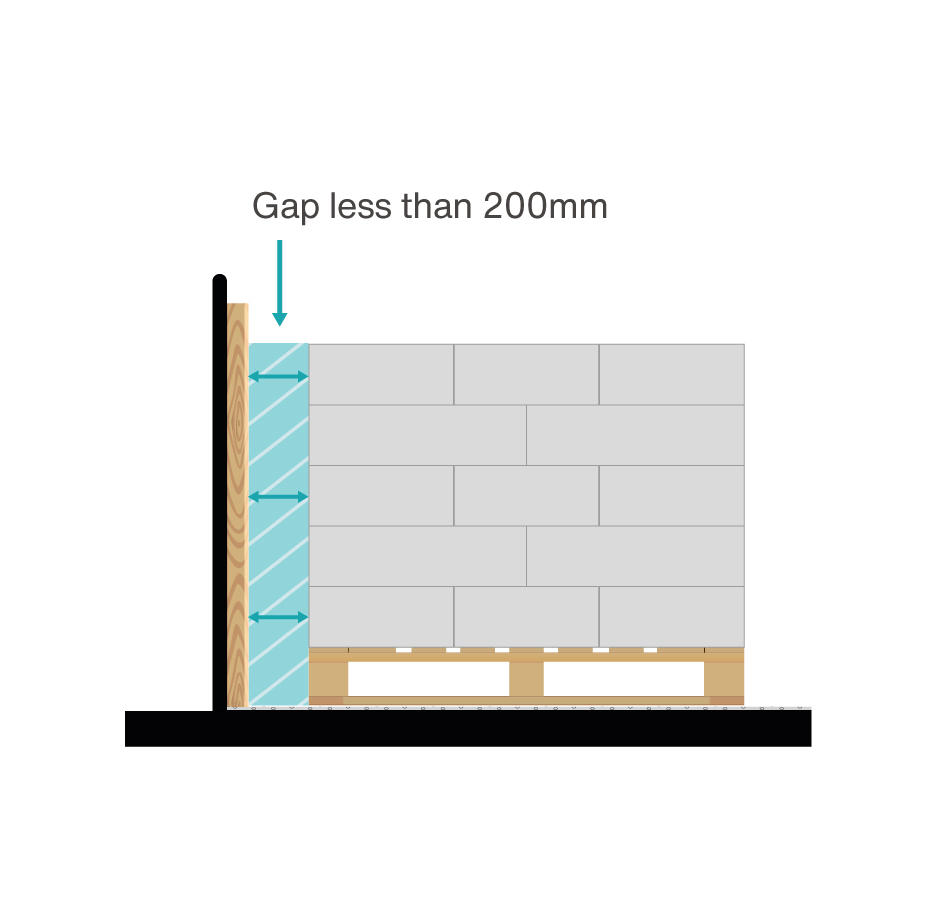

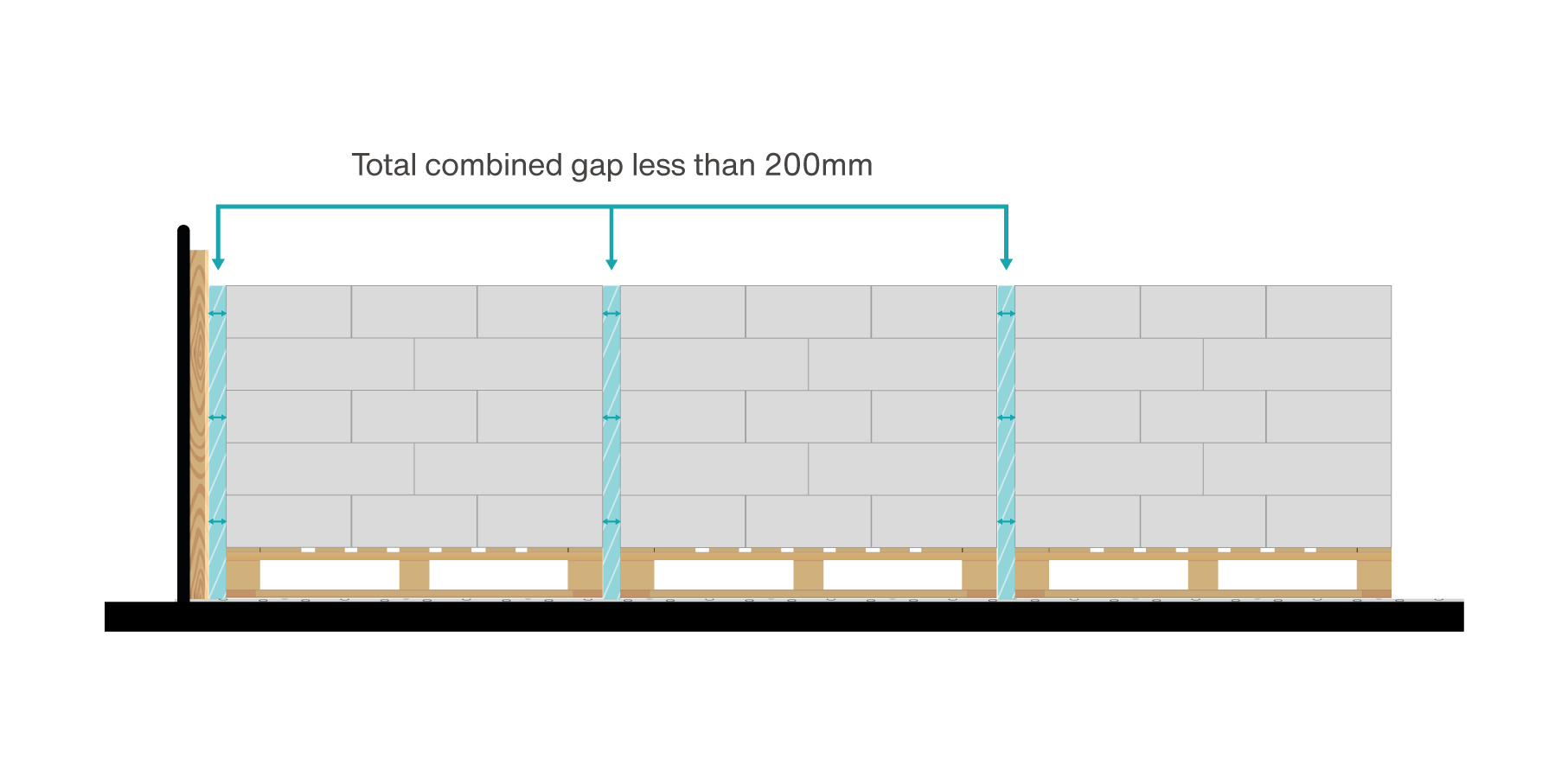

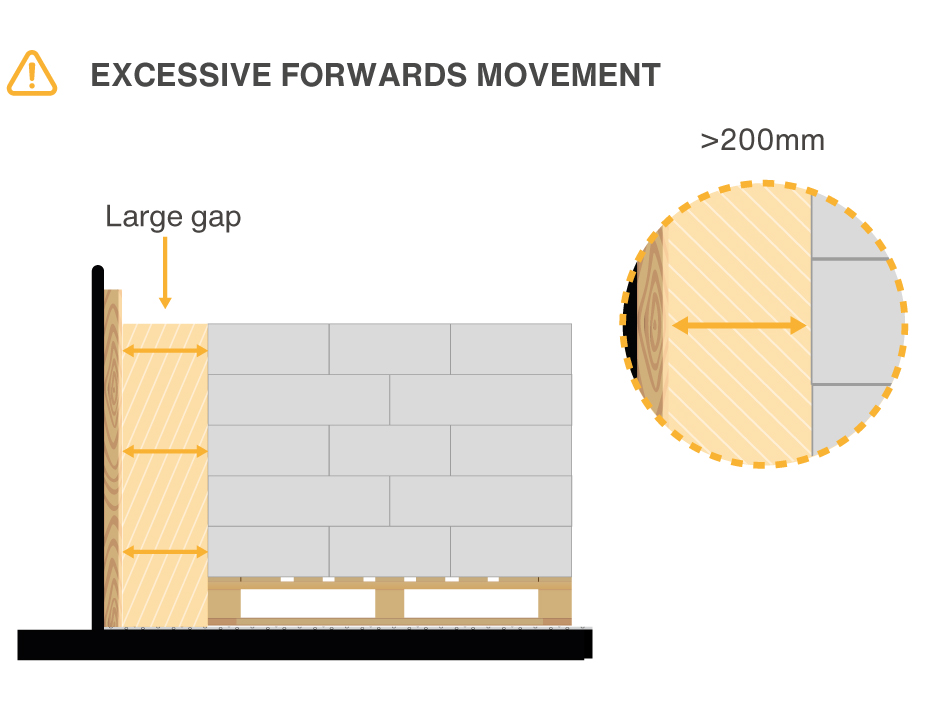

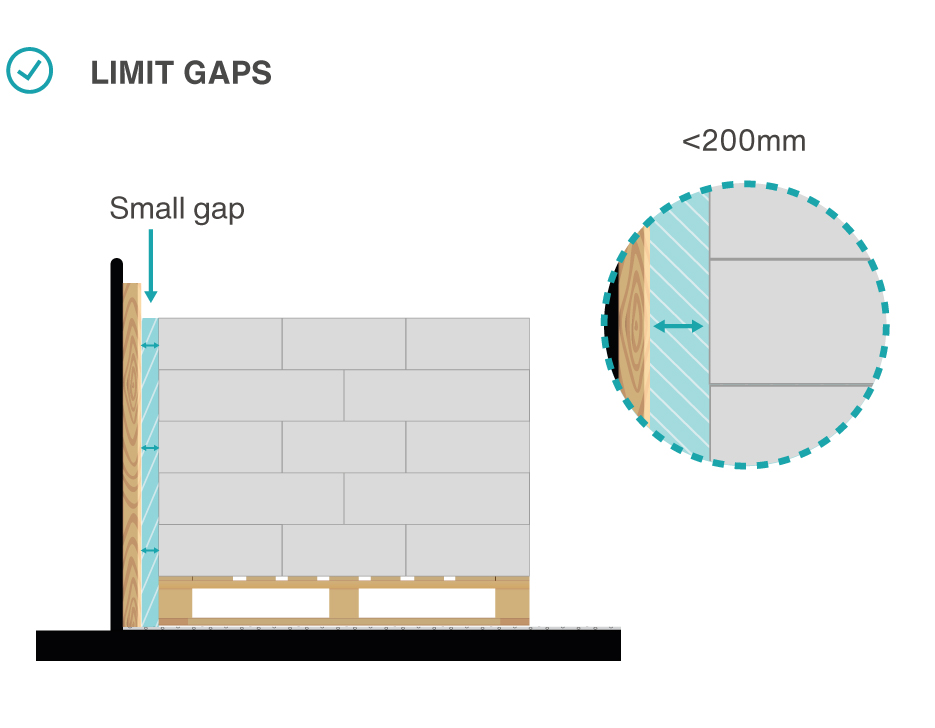

It’s important that any gaps between the load and any body structure or attachment does not exceed 200mm. The 200mm gap also applies to gaps along the length of the entire load (cumulative). This limits movement of the load under harsh braking events.

Why is Blocking important?

Blocking to prevent forward movement of the load is especially important when the load is placed directly behind the cab of the vehicle. In the event of a load restraint system failure, blocking the load provides protection to the occupants in the cab as it places a solid object between the load and cab occupants.

It is not a requirement to block loads, but it often means less restraint is required to comply with the loading performance standards.

Additional blocking techniques can be used where the load cannot be placed against the rated headboard.

Does blocking change the loading performance standards?

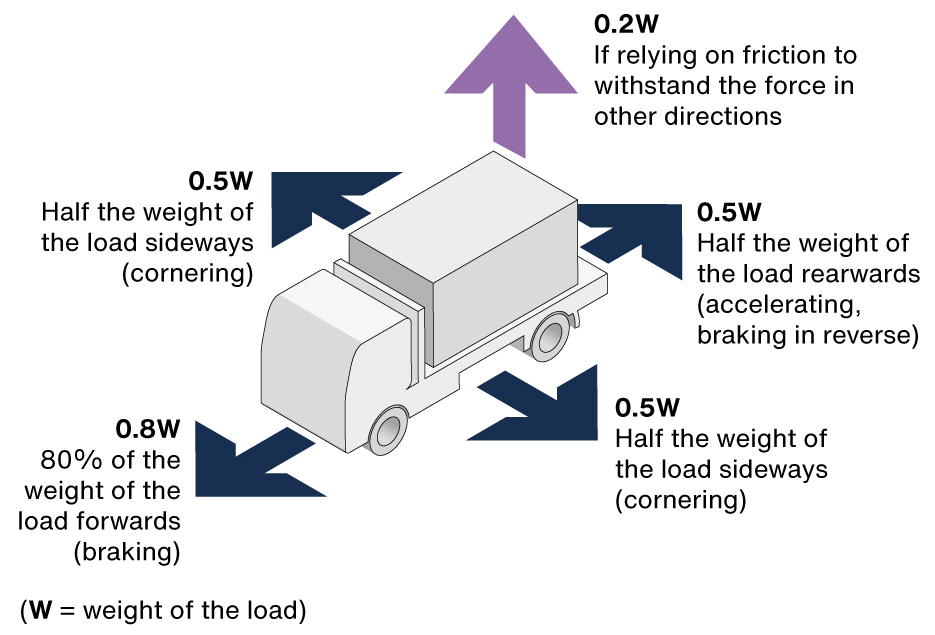

No, the loading performance standards in the forward direction is 0.8g or 80% of the weight of the load regardless of whether blocking is used or not.

The LRG provides two different approaches/classifications depending on whether the load is blocked or unblocked.

For the purpose of the LRG, the unblocked tables must be used if there is no blocking or a headboard is used that provides less than 0.3g or 30% of the weight forward restraint.

The blocked tables can be used if a headboard fitted provides at least 0.3g or 30% of the weight forward restraint.

These tables differ because of how much forward restraint is provided by the blocking.

Where blocking provides at least 0.3g/30% of the forward restraint, the other restraints only need to provide 0.5g/50% to add up to the 0.8g/80% required by the standards.

Where blocking that provides less than 0.3g/30% forward restraint is used, it is assumed it provides no forward restraint, so the other restraints (lashing etc) need to provide the full 0.8g/80% forward restraint.

An example of a rated headboard for a semitrailer might consist of a welded structure at the front of the trailer being manufactured from 3mm thick 100mm x 100mm square steel that has been certified to restrain a certain mass or load type by a suitably qualified engineer.

This is just an example, the size and dimension can change, but what’s important is that it has been certified by the manufacturer or a suitably qualified engineer.

What does Blocking look like?

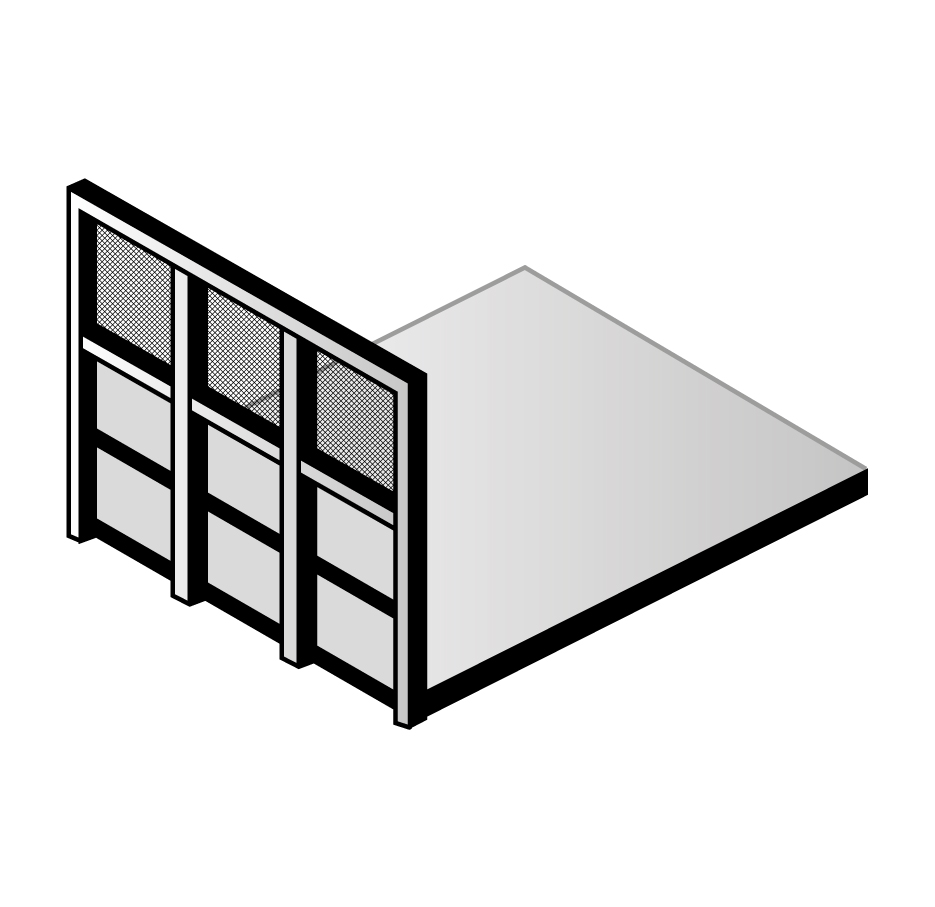

Examples of blocking structures and attachments may include:

Rated headboard

Reinforced tubular headboard

Rated side gates

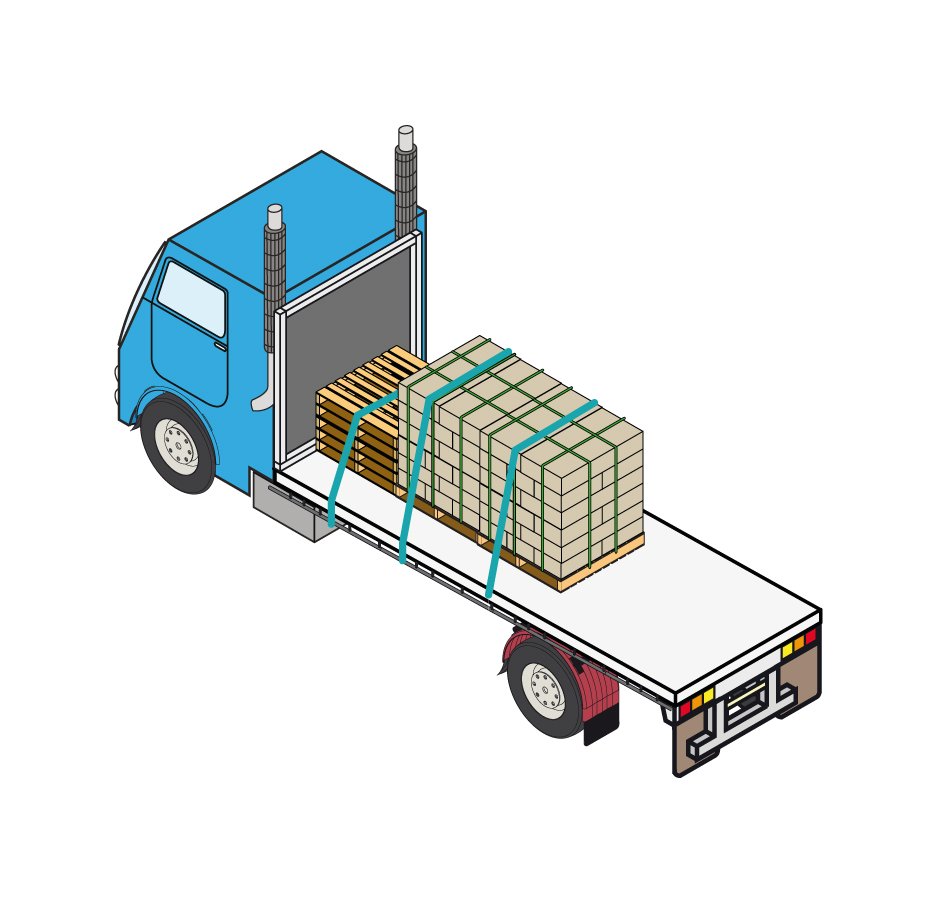

Rated moveable structures

Using webbing straps

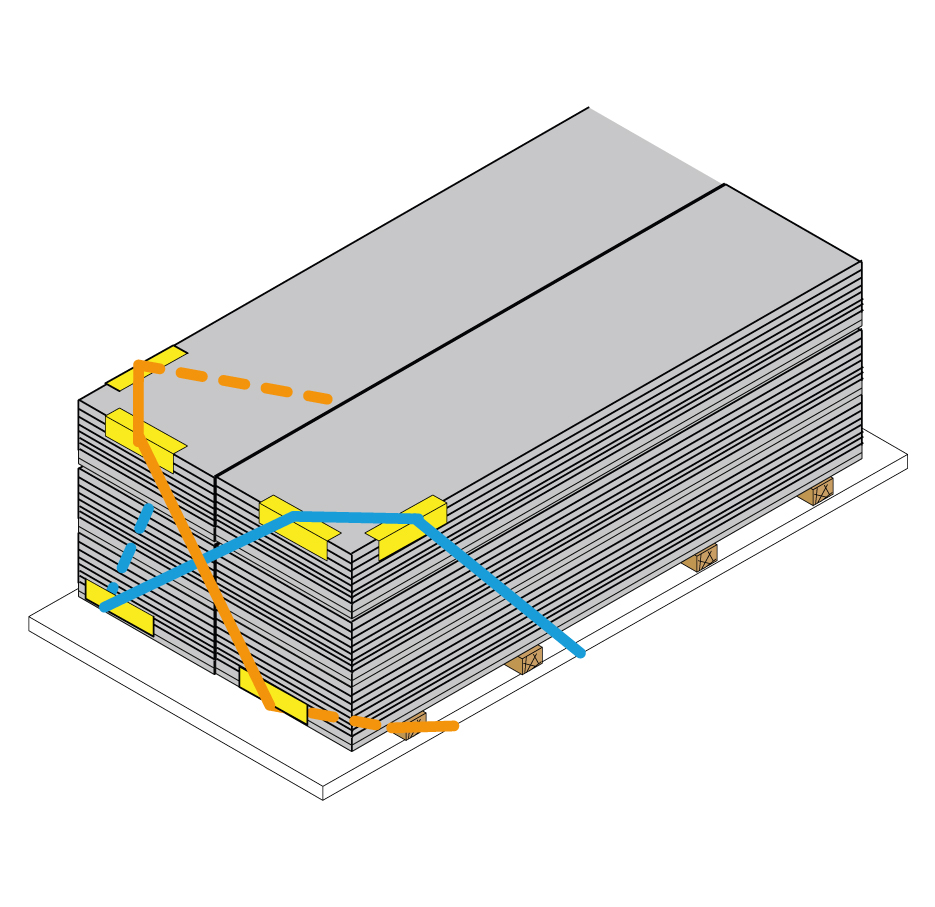

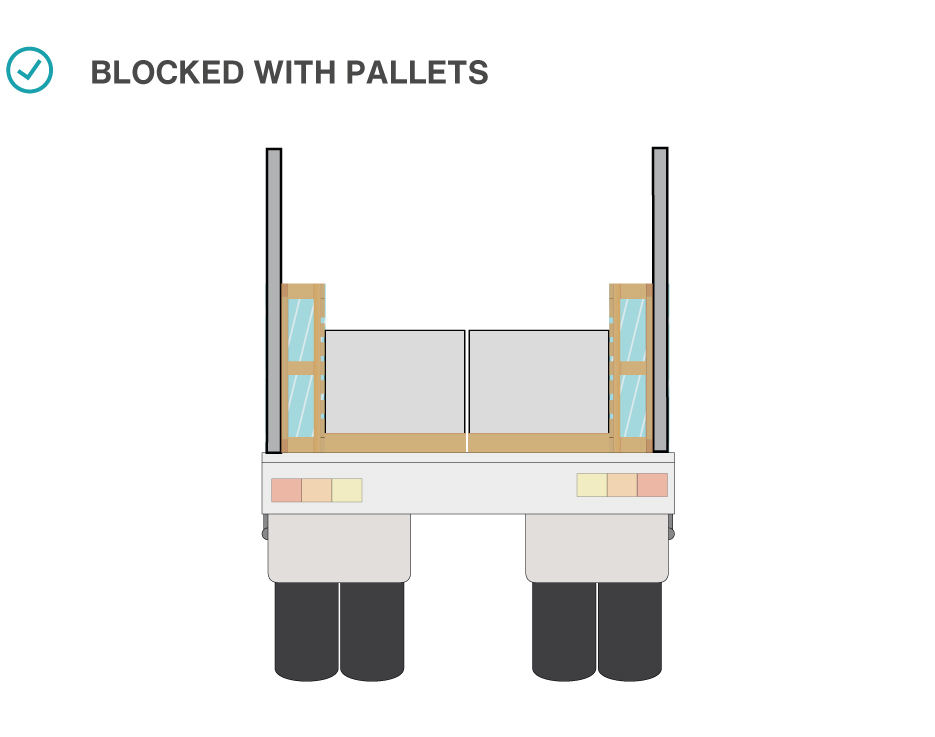

Blocking with pallets

Rated shoring bars

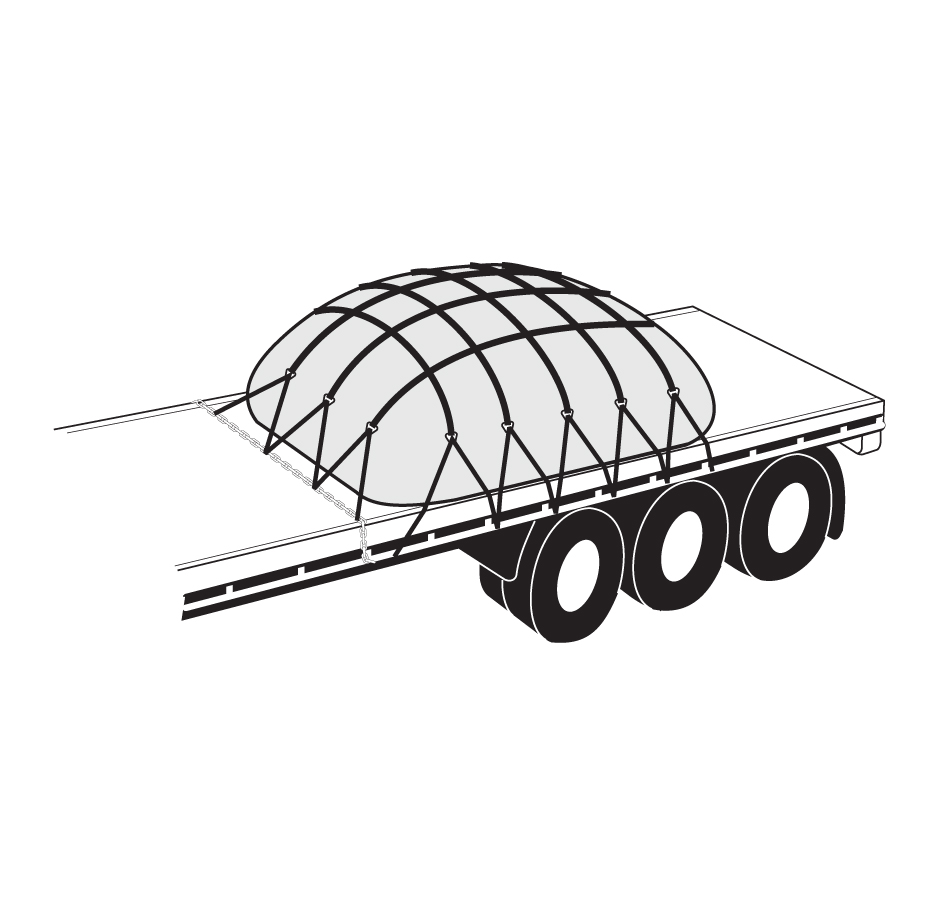

Rated cargo nets

Vehicle structure - step decks

Sides of a vehicle or tray

Tips

When blocking any load, the body structure or attachment should be rated.

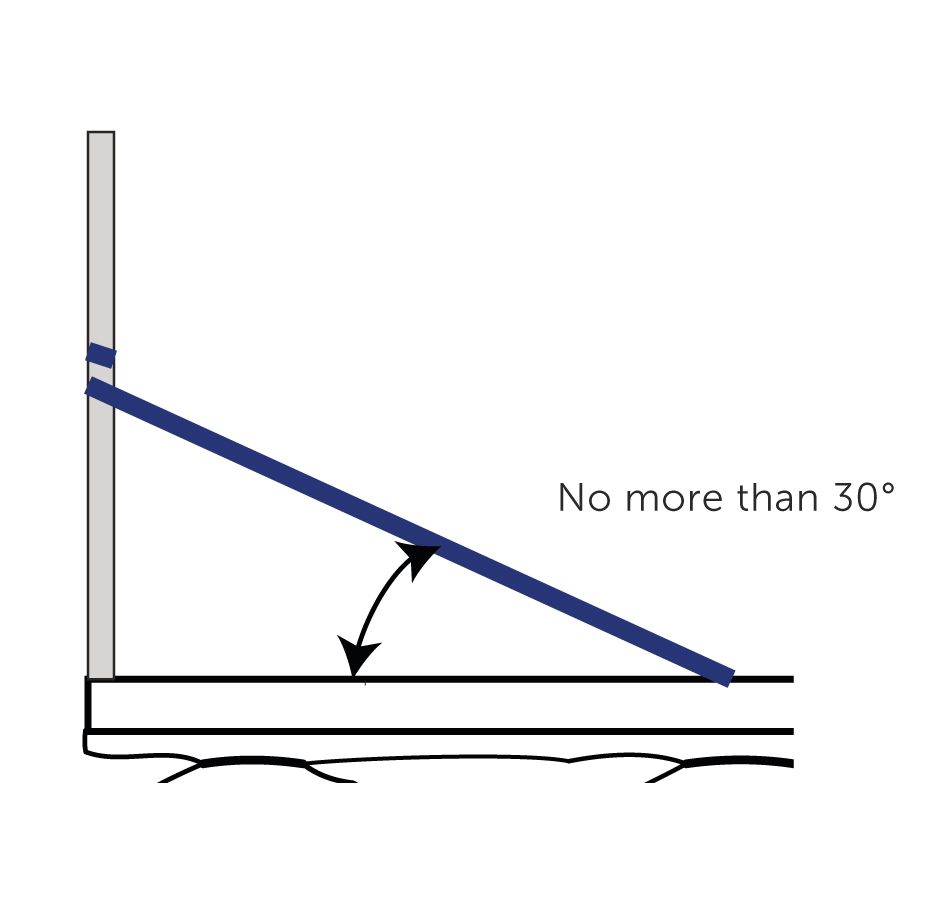

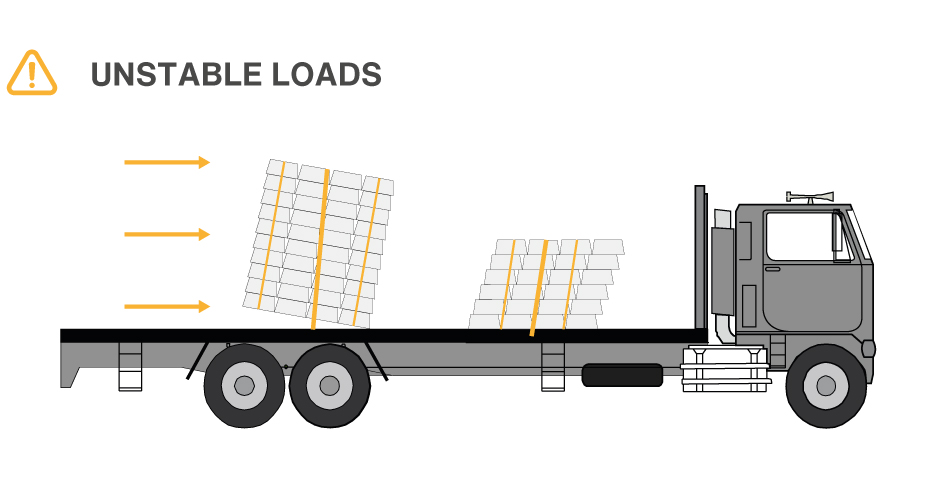

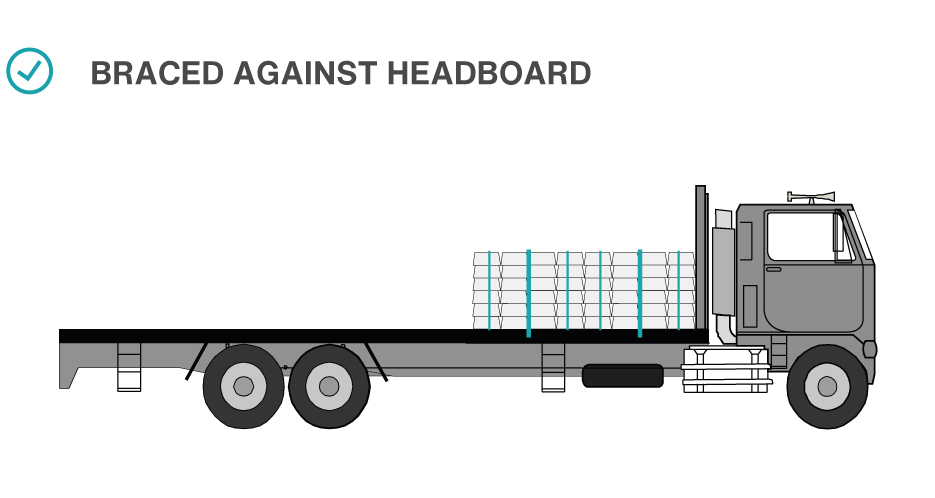

Tall loads may become unstable during transport. To help prevent the loads from tipping, block them against a headboard where possible.

Risks

Good practice

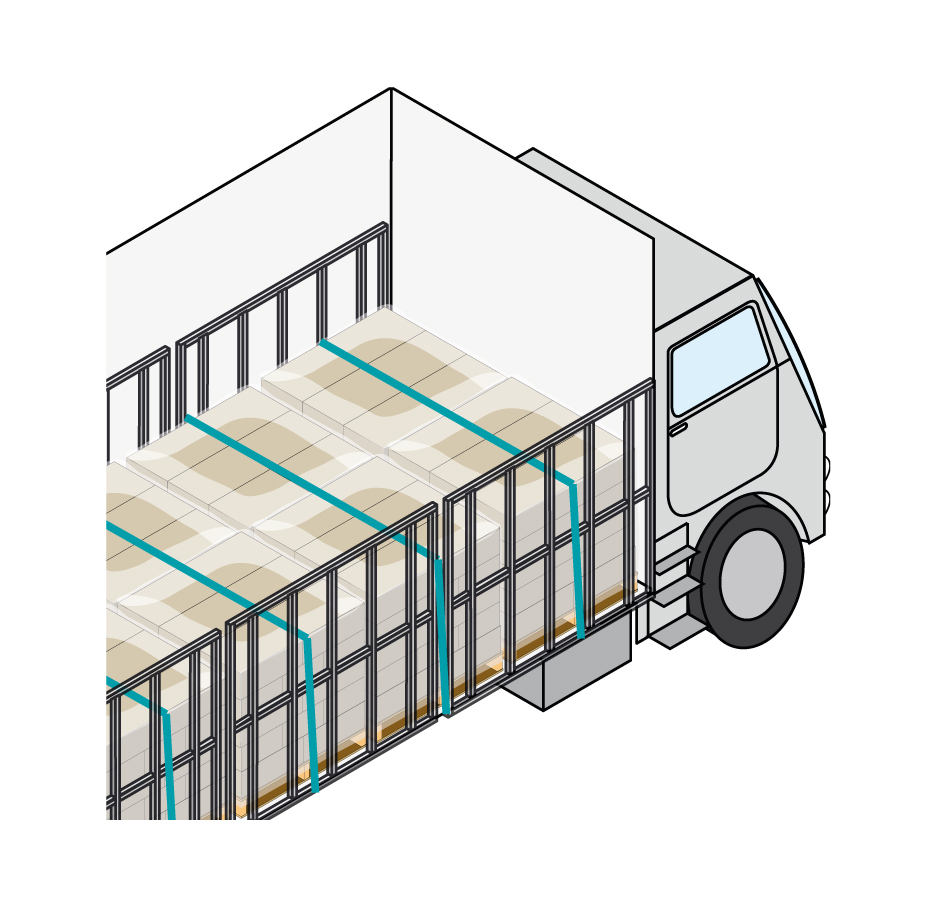

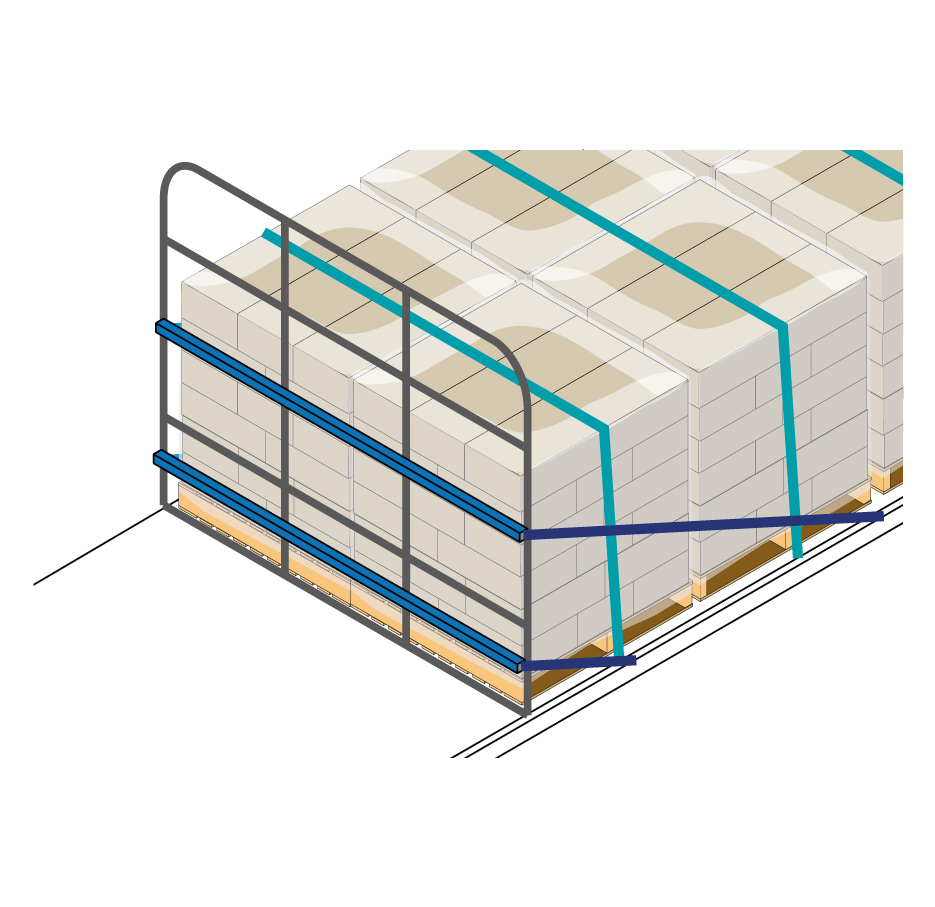

Position the load as close as practical to the headboard or loading rack. Within 200mm of the headboard is generally considered blocked.

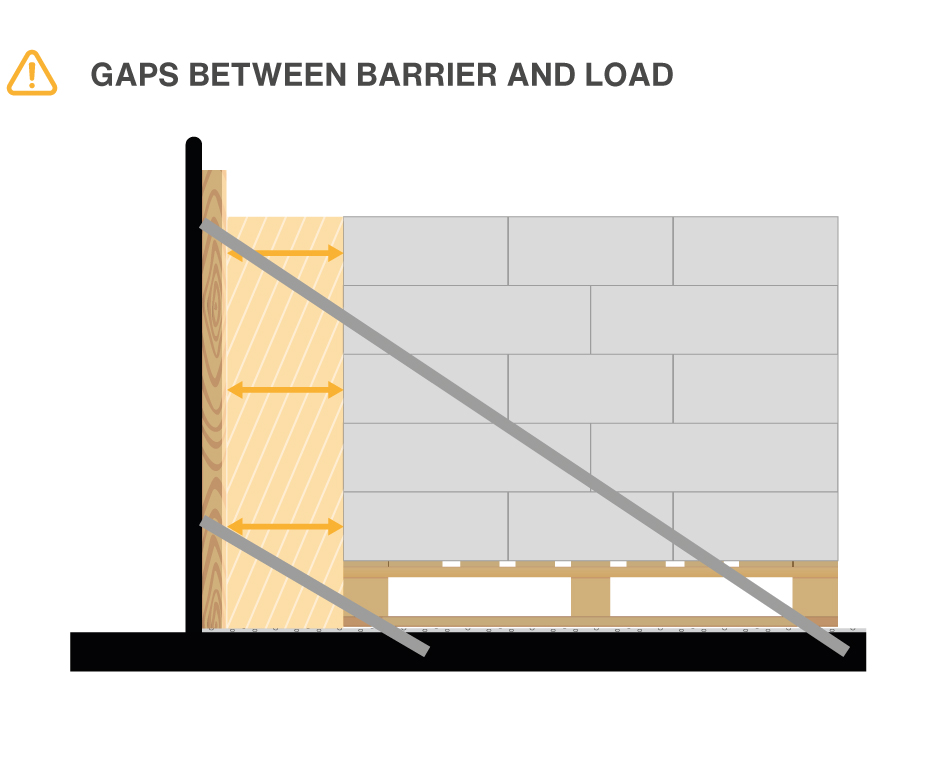

Risks

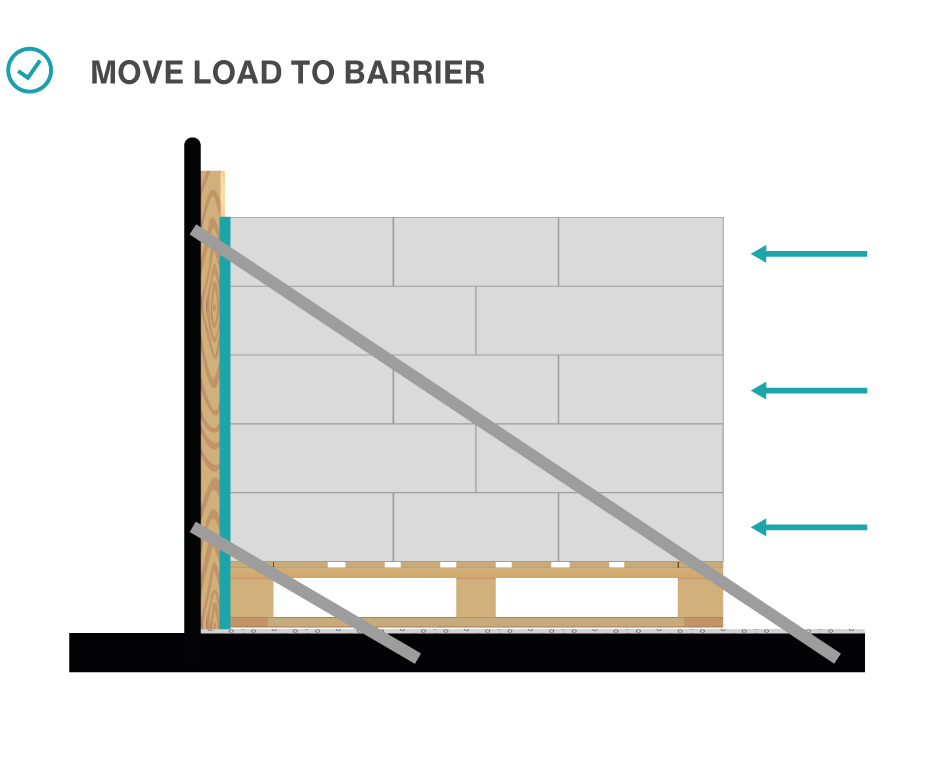

Good practice

If you have movable barriers, make sure they're against the load. Make sure that the barrier and its support chains are strong enough to block the load.

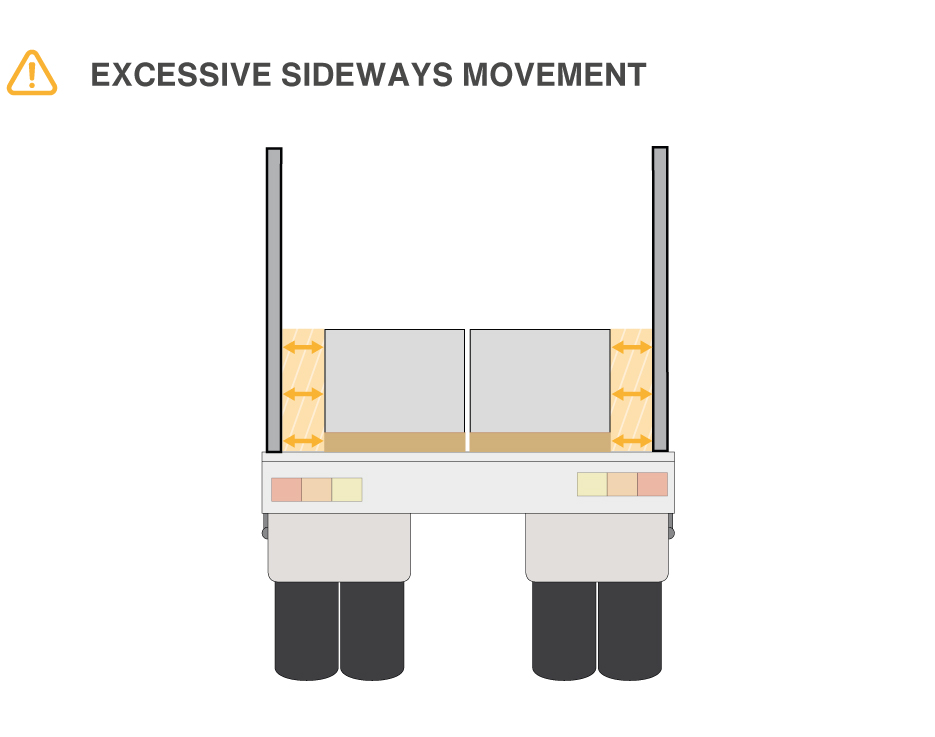

Risks

Good practice

Excessive sideways movement can affect stability. Fill gaps with timber pallets or other suitable material. Total sideways gaps should be less than 100mm.

Risks

Good practice

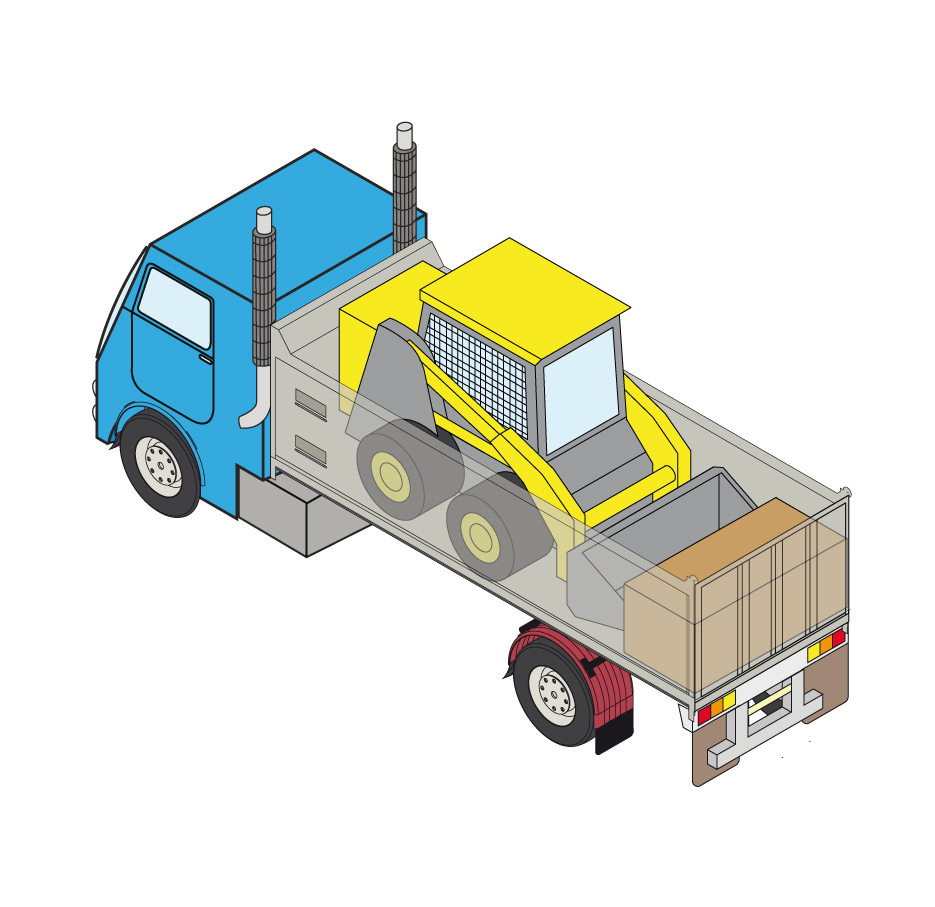

Case study

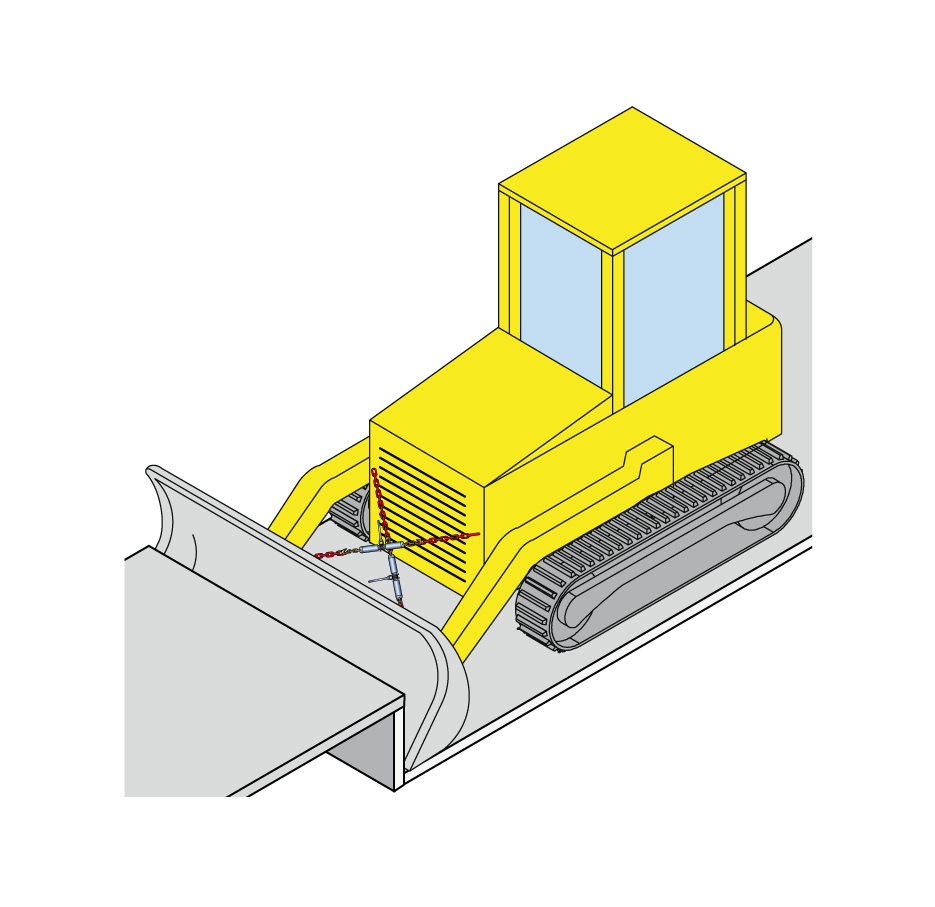

A heavy vehicle was loaded with a shipping container, and inside the container was a load of steel beams. This load is clearly not blocked from moving forwards, rearward, or sideways.

If the driver of the vehicle had to stop in a hurry or had been involved in a minor crash, this steel would all move forward. The further a load moves, the more energy it develops and the more damage it will cause, that’s why you must minimise any gaps. Shipping containers are not designed to withstand the forces generated by the unrestrained steel beams. In this instance, a load shift could result in serious injury or death, not only to the driver but also to other road users and can also result in damage to road infrastructure.

Often loads just get placed inside shipping containers, and it’s assumed the load is contained, it is not.

To properly restrain this load requires a structure built or blocking material placed around the load or internal restraints to stop its movement and it should’ve been inspected and certified by a qualified person to ensure it was safe for transportation.

Accessibility tools

Accessibility tools