Loading Guide - Covering Loads

Loading Guide - Covering Loads

National

Heavy

Vehicle

Regulator

This guide is part of a series of loading guides that provide tips and tricks to help you understand good load restraint. More detailed information on the principles covered by this guide can be found on page 90 of the Load Restraint Guide 2025.

What are load covers and how are they used?

A load cover is a protective covering used to secure and protect freight during transport. They are usually made from durable materials such as canvas or vinyl and are used to:

- Protect loads from contamination from dust or other environmental factors such as rain or direct UV light

- Form part of a load restraint system for loads that may become dislodged by air movement whilst in transport, such as sand, soil or other fine/light loose bulk loads.

Do I need to cover my load?

Not all loads require covering. Whether a covering is required will depend on the type and size of the load.

Covering a load supports the safe and effective transport of loose bulk loads, particularly those vulnerable to wind effects. If there is a risk of the load becoming dislodged due to air flow or road conditions, covering the load is an effective method that could be used to control the potential loss of the load.

Although load covers are beneficial, they should only be used as part of a load restraint system. Load covers are not required if the load is already securely contained and restrained and is not likely to become dislodged, spill or create dust.

Types of load covers

- Tarpaulins (Tarps): Heavy-duty, weather resistant sheets designed to protect loads from weather and dust. Tarps often have reinforced fittings at the corners and along the sides to form attachment points for rope, allowing them to be tied down or suspended.

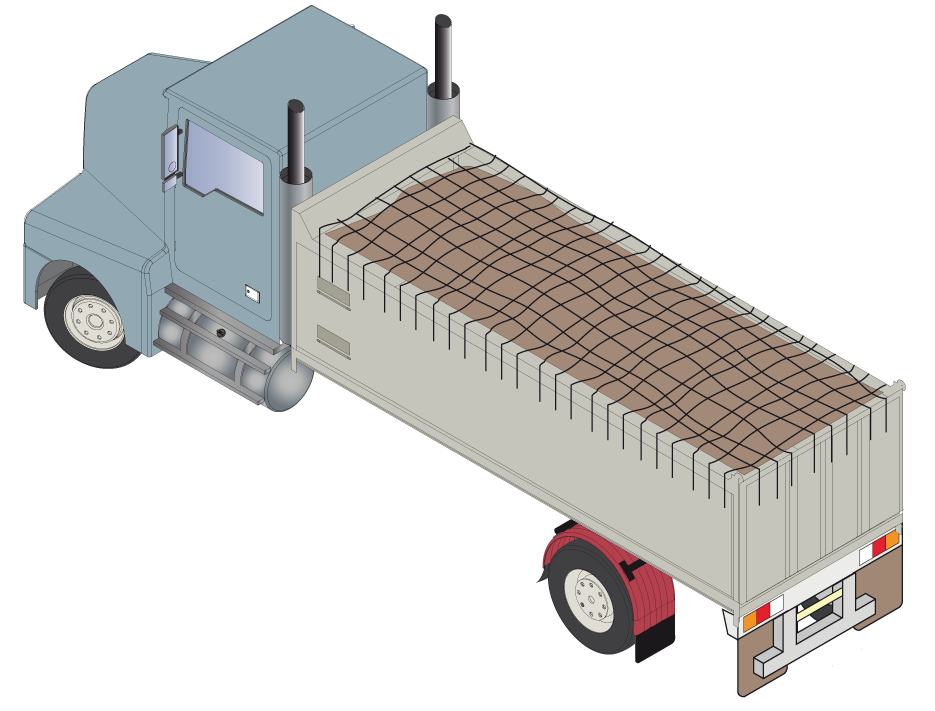

- Mesh/Canvas covers: Durable, breathable covers that provide protection while allowing ventilation, suitable for loads not prone to dust and moisture.

- Load nets: Flexible, durable nets used to contain and secure loads, preventing movement and spillage while allowing visibility and ventilation. The mesh size in the net should be smaller than the items being carried and strong enough to prevent any load from escaping.

- Custom covers: Tailor-made covers designed specifically for unique loads or vehicles to ensure optimal fit and protection.

Examples of loose bulk loads and how to cover them

Granular/powdered

- Sand

- Grain

- Soil

Cover using tarpaulins or custom load covers.

Cover using tarpaulins or custom load covers.Lightweight

- Tree foliage

- Wood chips

- Sugarcane billets/trash

- Loose Scrap metal

Cover using tarpaulins, mesh or netted load covers.

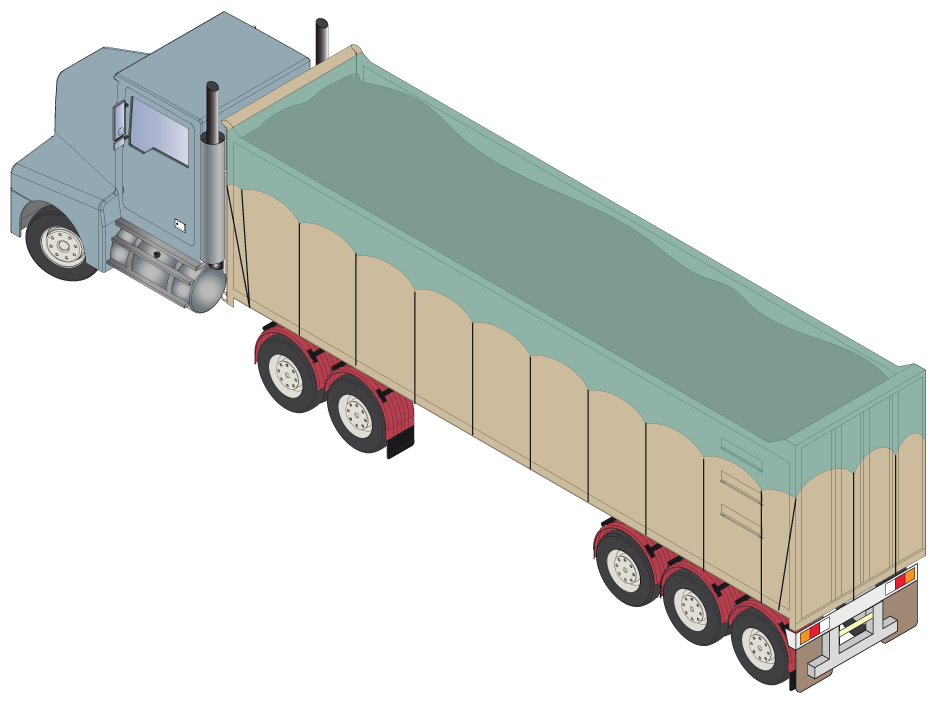

Cover using tarpaulins, mesh or netted load covers.Heavy

- Building materials

- Quarried rocks

- Mining products

- Chopped wood

Cover using tarpaulins or load nets.

Cover using tarpaulins or load nets.Each of these loose materials can be affected by conditions leading to potential issues, such as:

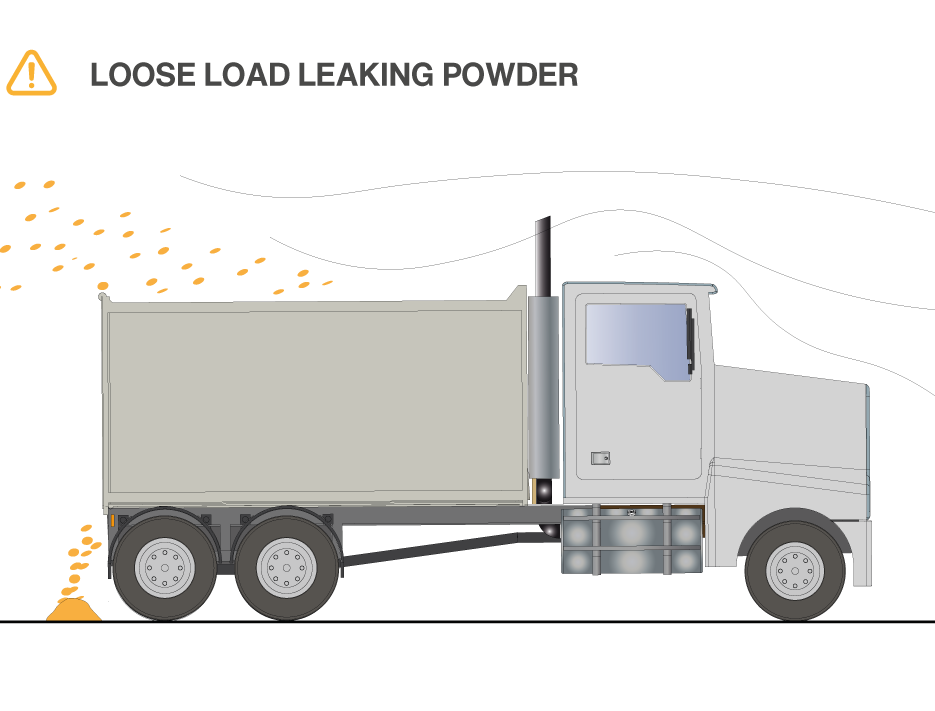

- Dust creation: Air flow over the vehicle during travel can pick up fine materials, creating dust that may cause environmental concerns or safety issues for other road users.

- Spillage: Uncovered loads can spill, become dislodged or bounce out of the vehicle during transport, causing hazards on the road.

Tip: When transporting loose bulk loads, choose an appropriate vehicle that contains the load, such as tippers or a fully enclosed tanker to prevent product loss.

Do not transport lose bulk loads on tabletop bodied vehicles without sides or gates, or tipper bodies without properly fitting tailgates.

Do covers need to be load rated?

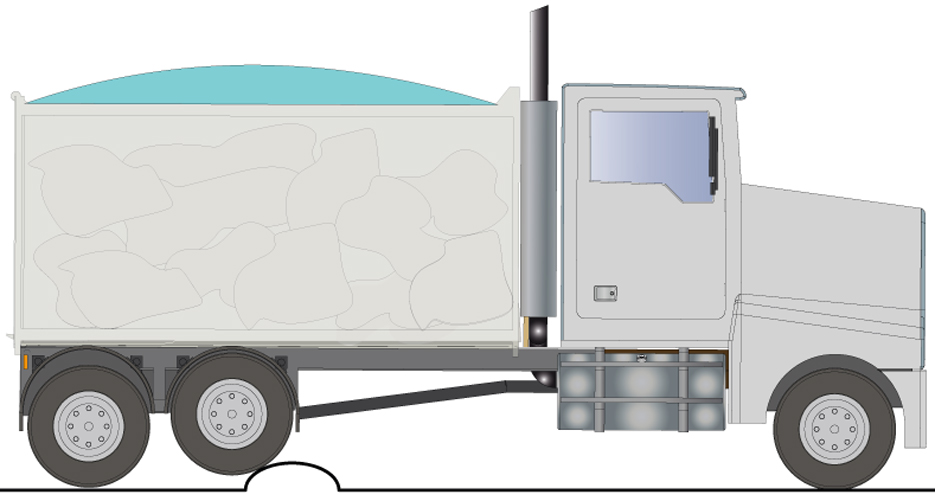

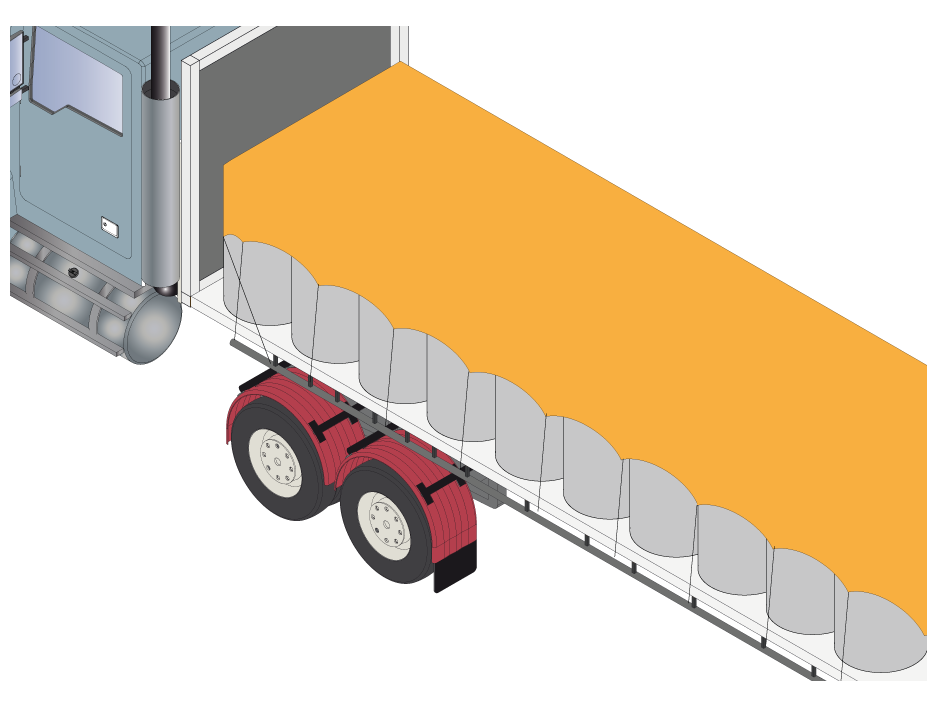

All covers should be rated or specified for the type of load they are intended to cover and designed so it can be effectively secured to the vehicle body. Tarps are primarily designed to protect loads from weather and dust, while also preventing loose bulk loads from being dislodged by airflow during travel. They form part of the containment method but do not count toward load restraint calculations for tie-down and direct methods, which must also include other restraint systems such as straps or chains to secure the load effectively.

Tarpaulin without load restraint.

Tarpaulin without load restraint.Tips for using load covers

Selecting the right cover and using it correctly is important for ensuring the safety and stability of your load as part of a comprehensive load restraint system.

Remember to:

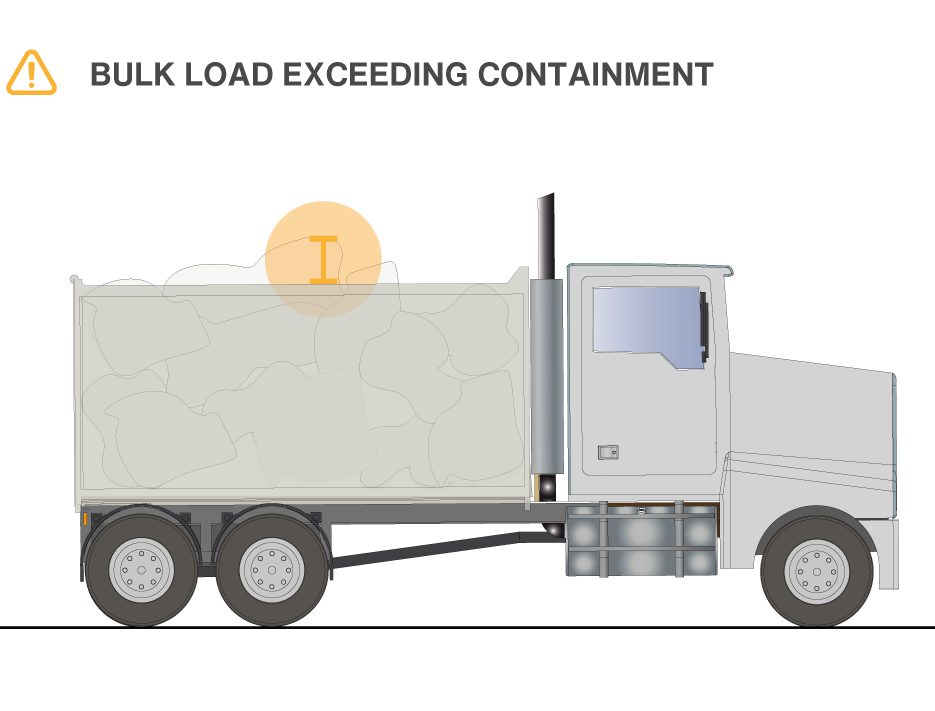

- Have appropriate coverings for any loose bulk loads that are loaded higher than the sides of the container walls (tipper body).

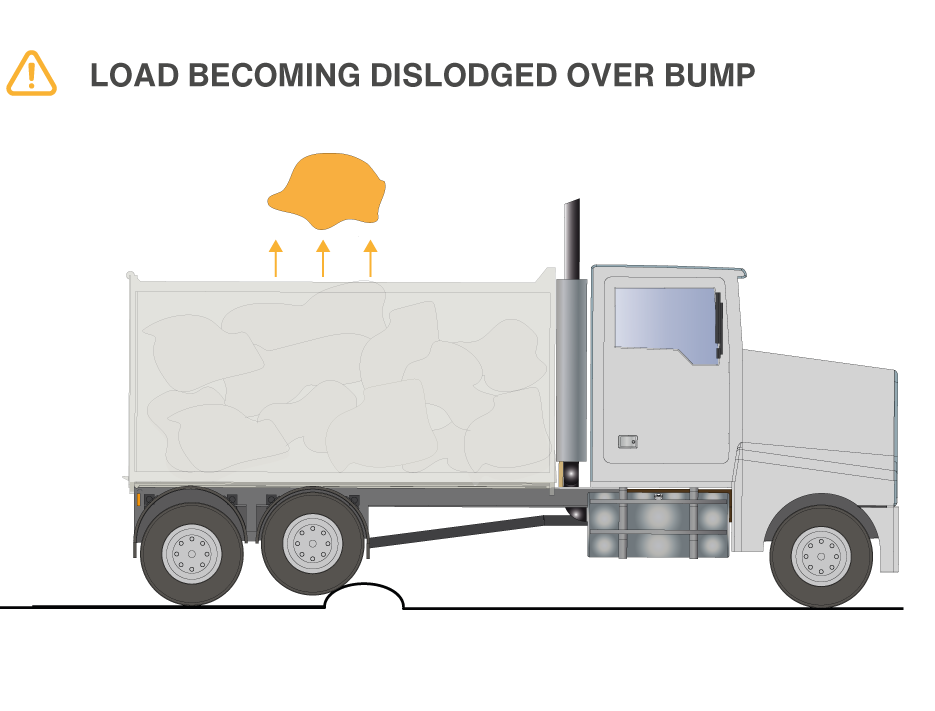

- Be aware that even if loads are not higher than the container walls, they can still become dislodged by airflow or when travelling over uneven road surfaces.

- Use load covers in combination with wetting or skinning agents for longer journeys. While wetting or skinning agents can restrain fine particles for short periods of time, they should be used with a suitable load cover for extended distances.

- Check that lights, reflectors, number plates and rear markings are not covered.

- Inspect covers for any loose sections or tears that may cause the load to become dislodged or sections of the cover separating from the vehicle during transport. This could pose a danger to other road users.

Case study

Two heavy vehicles were loaded, one with a large quantity of chopped wood, and another with sand. Both vehicles had their loads piled higher than the sides of the tipper body. In both cases, the loads were not covered, leaving them in danger of shifting or spilling during transport.

If the vehicles had come across uneven road surfaces during the journey, loose wood or sand could have easily spilled out onto the road. This could impact other vehicles on the road by leaving debris or creating dust that blocks drivers’ views, leading to hazardous driving conditions and potentially causing incidents.

A properly secured tarpaulin or load net would have kept the chopped wood in place, while a tarpaulin or custom load cover would have been ideal for the sand. Using appropriate load covers in these cases would have ensured the loads remained secure and safe, reducing the risk of incidents or harm to other road users.

Failing to cover loose bulk loads can lead to serious hazards, endangering the driver and other road users and increasing the risk of serious injury, death or breaching Heavy Vehicle National Law (HVNL).

Accessibility tools

Accessibility tools