Loading Guide - Load Distribution

Loading Guide - Load Distribution

National

Heavy

Vehicle

Regulator

This guide is part of a series of loading guides that provide tips and tricks to help you understand good load restraint. More detailed information on the principles covered by this guide can be found in the Load Restraint Guide 2025.

Why is load distribution important for safety?

The position of a load has a significant impact on the safety of a heavy vehicle as it impacts the vehicle’s stability, steering dynamics, braking and weight distribution.

For example:

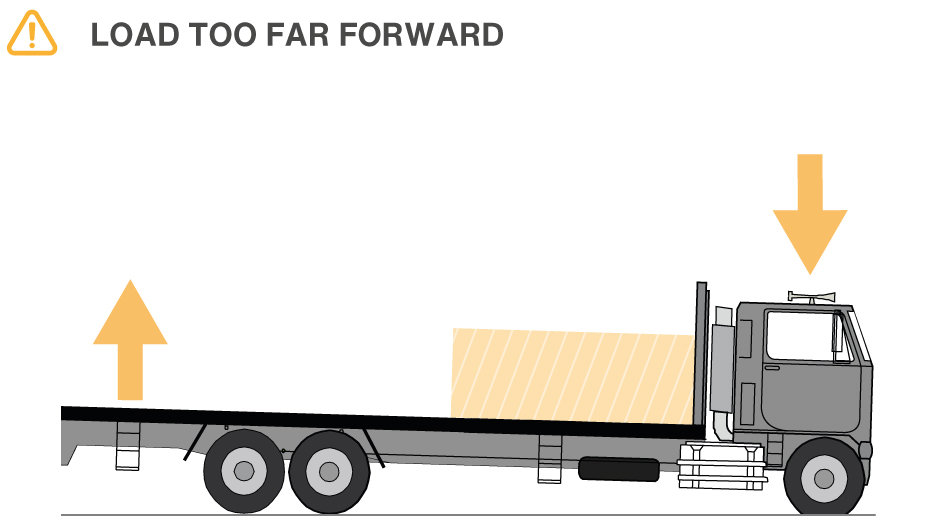

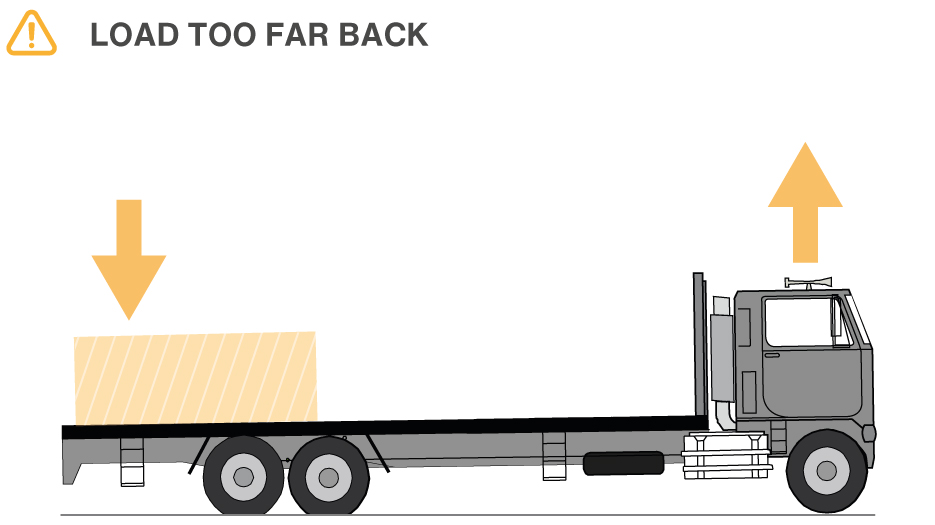

- Placing a heavy load too far to the rear of the vehicle will affect the vehicle’s steering and braking performance and too far forward may cause the rear brakes to lock up, especially in wet weather.

- The placement of heavy loads can impact on axle mass limits.

- Uneven weight on the wheels influences the braking performance and can cause individual wheels on axles to lock up.

How does load distribution affect vehicle safety?

Getting the load distribution right is really important when it comes to safety.

Later model heavy vehicles equipped with Euro V or VI emission and other safety technology are more susceptible to exceeding the steer axle mass limits.

Improper load placement can mean axle mass limits are exceeded even when GVM is compliant.

Placing a load to far forward may cause the vehicle to exceed its steer axle limit and if it is too far back, the vehicle may exceed the drive axle limit.

Placing a heavy load behind the rear axle/axle group should be avoided as it may unload the mass on the steer axle, making steering less predictable.

Risks

Risks

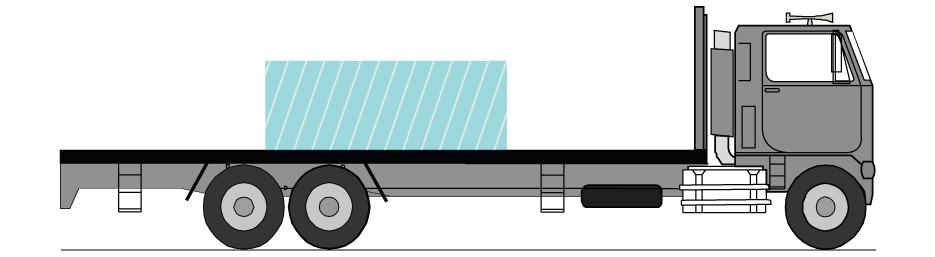

Good practice

Where can I get this information?

Information for load distribution can be obtained by contacting the manufacturer of the vehicle in the first instance. You can also use a public weighbridge or private weighing service to better understand how load placement affects mass distribution.

Software is also available to assist with load distribution and complying with axle and gross mass limits.

Professional advice may be especially relevant if you are designing a custom load distribution plan specific for your freight task, or if you’re transporting something unusual, like a large indivisible item.

Case study

How did this load of just two 1000L IBC’s exceed axle weights limits on a 23t truck?

The load of around 2 tonne was placed behind the headboard of the rigid heavy vehicle.

Because the design of the vehicle meant the centre of the mass is towards the front of the vehicle, that is most of the unladen mass is distributed towards the front of the vehicle through the steer axle. By placing the relatively small load towards the front of the vehicle this increased the loading on the steer axle which was already close to axle mass limits.

When the vehicle was stopped for a safety check at one of the NHVR safety stations the Safety and Compliance Officers were surprised to find the weights below.

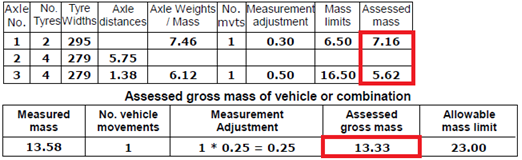

Steer axle assessed mass 7.16t, allowed 6.5t, that’s a 660kg or 110.1% overload.

Drive axle assessed mass 5.62t, allowed 16.5t, well under the allowed limit. Gross Mass, 13.3t, allowed 23t, well under the GVM.

Actual weighing data below.

If the load had been placed further towards the rear axle group, more of the load would have been carried on the rear axle group and assisted in keeping the steer axle within mass limits. More evenly distributing the load to the rear of the vehicle also would have ensured better braking performance.

If you would like to know more about the weighing process see Measurement adjustment.

Note: The load restraint is also insufficient, for more information see Loading Guide – Intermediate Bulk Containers (IBCs).

Accessibility tools

Accessibility tools