Loading Guide – Loading Plans

Loading Guide – Loading Plans

National

Heavy

Vehicle

Regulator

This guide is part of a series of loading guides that provide tips and tricks to help you understand good load restraint. More detailed information on the principles covered by this guide and examples of working out load restraint can be found on page 204 of the Load Restraint Guide 2025.

What are loading plans?

Loading plans describe how loads are packed, where loads should be placed on the vehicle and the minimum requirements to safely restrain the load for transport by road.

Why should I use loading plans?

Loading plans provide a repeatable process to ensure specific loads on heavy vehicles are transported safely and efficiently. The use of loading plans can streamline processes, saving time and money and improve compliance.

Loading plans take the guesswork out of compliance by providing information such as:

- weight of the load

- vehicle selection (size and length, load capacity)

- where to position the load on the vehicle

- dunnage/friction mat requirements and location

- detailed information on how to restrain the load and what equipment is needed

- centre of gravity of the load

- packing or packaging requirements

- if the load needs to be segregated (dangerous goods)

- health and safety information

- contact details for responsible entity

- any known hazards or risks

- certification statement.

What do loading plans look like?

There is no set format for what a loading plan must look like, it will depend on the individual business needs and the equipment/product being transported. They may be multi-page documents or a single page depending on the level of detail required.

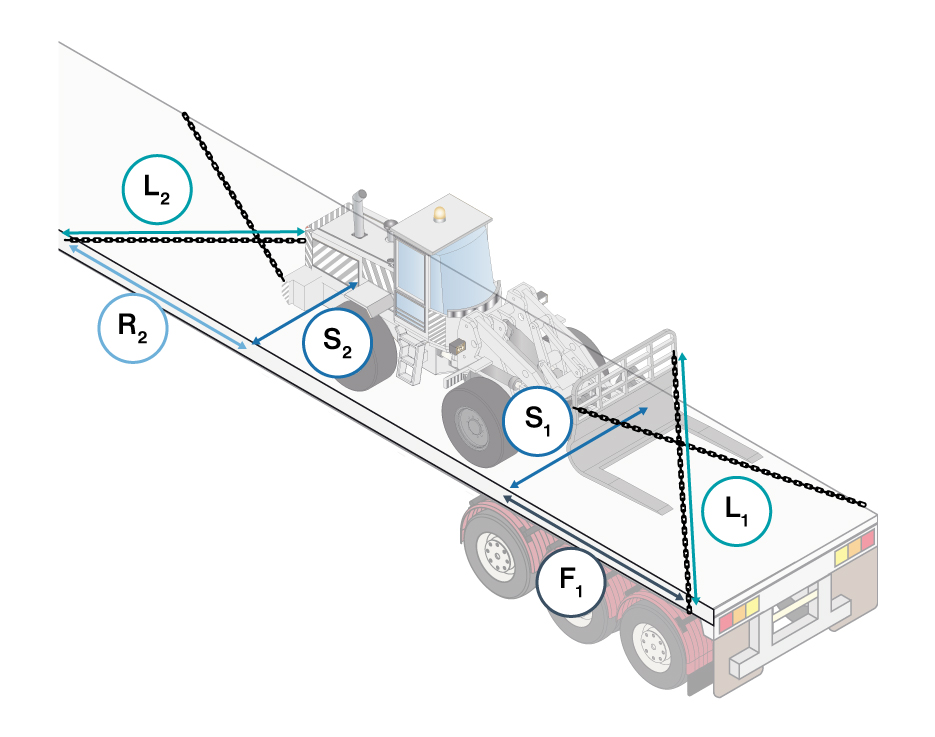

The 12 worked examples (case studies) from page 204 onwards of the Load Restraint Guide, provide examples of information loading plans may contain. Below is information for a 15t loader from Case 7 on page 223. It provides clear instruction on chain size and placement to meet the loading requirements. The A3 poster on this page is an example of how this information can be used to create a loading plan.

| Description | Front | Rear |

|---|---|---|

| Lashing (chain) (longer chains used to cross the deck) | 4,000 mm (L2 in diagram) |

4,000 mm (L1 in diagram) |

| Distance between the tie points along the trailer | 3,400 mm (R2 in diagram) |

3,400 mm (F1 in diagram) |

| Distance between the tie points across the trailer | 2,000 mm (S2 in diagram) |

2,000 mm (S1 in diagram) |

The loading plan would also include information on lashing selection (webbing or chain), the load’s position on the vehicle, any requirement for the park brake application, position of lockout controls, other hazards and risks, and detailed diagrams to assist the user, etc.

Why should loading plans be shared?

Businesses that have developed and use loading plans should share them with business partners to ensure safety, drive consistency and mutual understanding of expectations and loading requirements. Making the most of business relationships with other CoR parties can be one of the most effective tools for managing safety and eliminating or minimising risks.

You may also choose to include loading plans in any contractual arrangements, so all CoR parties understand and agree upon how the load is to be restrained for transport on a road to ensure the safety for shared transport activities.

Where can I get the information needed to develop a plan?

Information required to develop a loading plan may come from multiple sources, such as the manufacturer of the equipment/product, the load restraint guide or a load restraint expert, other businesses, or industry associations as well as your own experience and expertise.

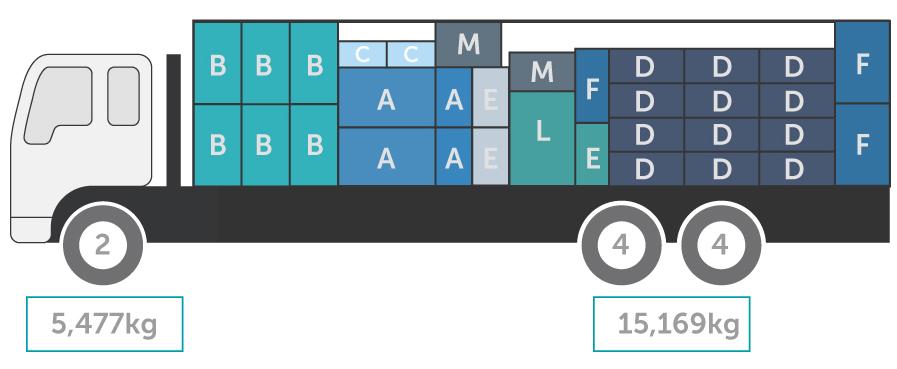

Software is also available to assist with load placement, drop off sequence and complying with axle and gross mass requirements.

Professional advice may be especially relevant if you want to design a custom loading plan for your specific freight task, or you are transporting something unusual or a large indivisible item.

Once you have developed a plan it should be independently validated to ensure it complies with the Heavy Vehicle National Law (HVNL) loading requirements and loading performance standards.

If the plan has been validated by an appropriately qualified engineer – it can include a certification statement that provides assurance to authorised officers. For more information on certification see page 236 of the Load Restraint Guide.

Accessibility tools

Accessibility tools