Loading Guide - Live Loads

Loading Guide - Live Loads

National

Heavy

Vehicle

Regulator

This page is part of a series of loading guides that provide tips and tricks to help you understand good load restraint. More detailed information on the principles covered can be found in the Load Restraint Guide 2025.

What are live loads?

Live loads are loads that can be expected to move when being transported.

This includes bulk liquids, livestock, hanging meat, wet concrete, motor vehicles and large rubber-tyred equipment.

Understanding Live Loads

Live loads that can move during transport pose additional loading and restraint challenges that must be considered to ensure safety. When a load moves during transport, additional forces are experienced by the load restraint system and the vehicle. These additional forces may be enough to cause the load restraint system to fail, cause the vehicle to become unstable or even roll over.

Operators should provide drivers with as much information as possible about the load they are transporting and highlight any hazards or risks that the load may present. Drivers are encouraged to seek advice from more experienced drivers to understand how a live load might behave during transport.

Hazards

- Livestock carriers – Livestock trailers have a relatively high centre of gravity and animals may move in transit, affecting a vehicle’s cornering ability and increasing rollover risk.

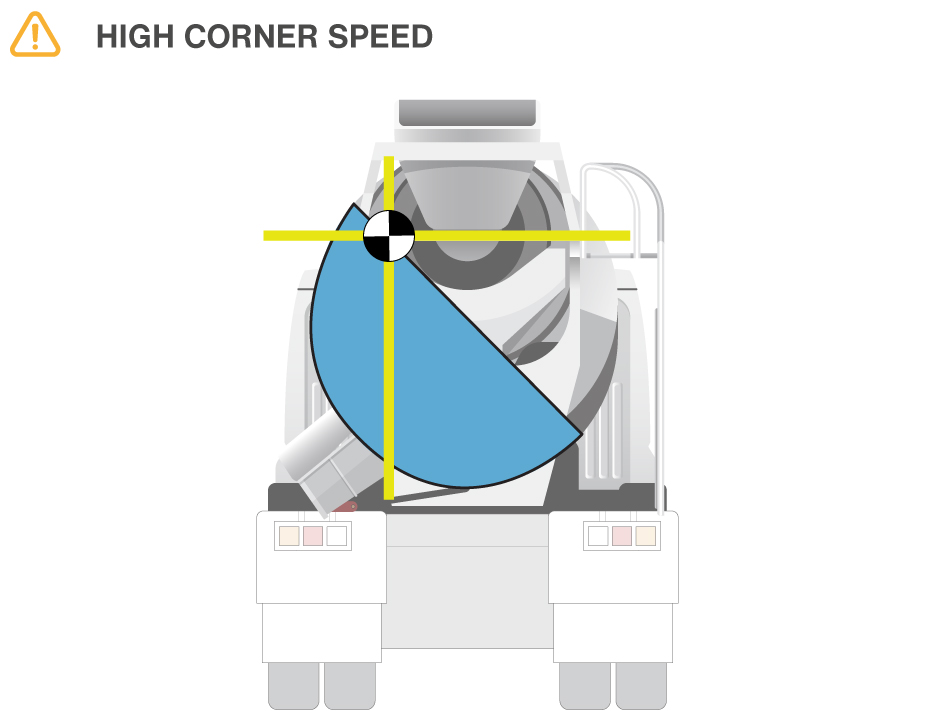

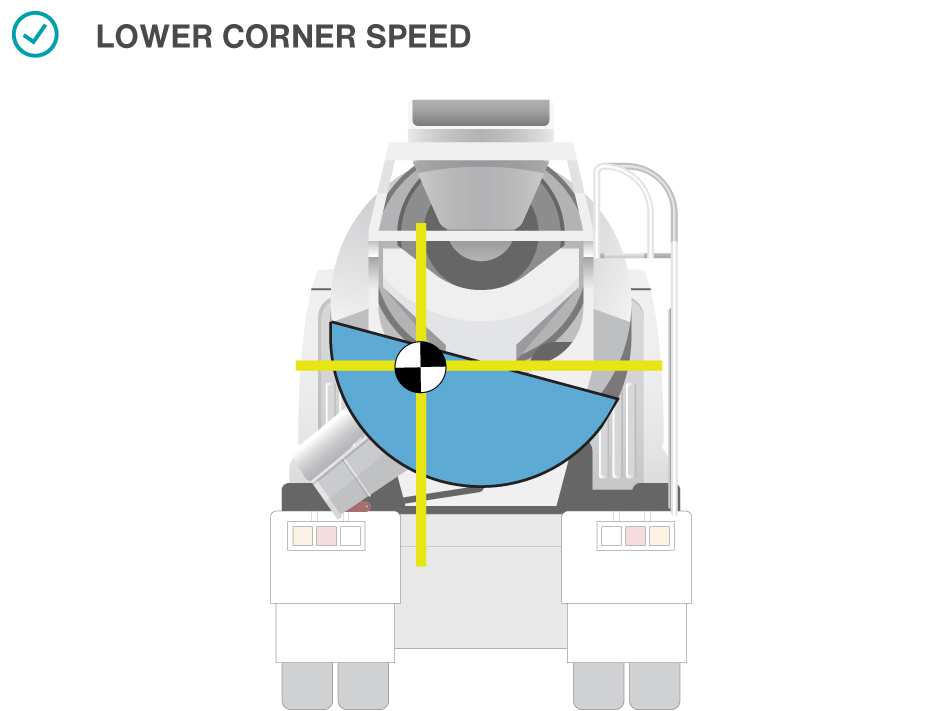

- Rotating loads – Loads such as wet concrete transported in agitators are less stable when turning corners as the centre of gravity of the load shifts up and to one side due to the rotation of the drum and liquid load.

- Shipping containers – Liquid loads inside a container can still affect a vehicles stability through liquid slosh and increased forces on the container structure, making the vehicle unstable.

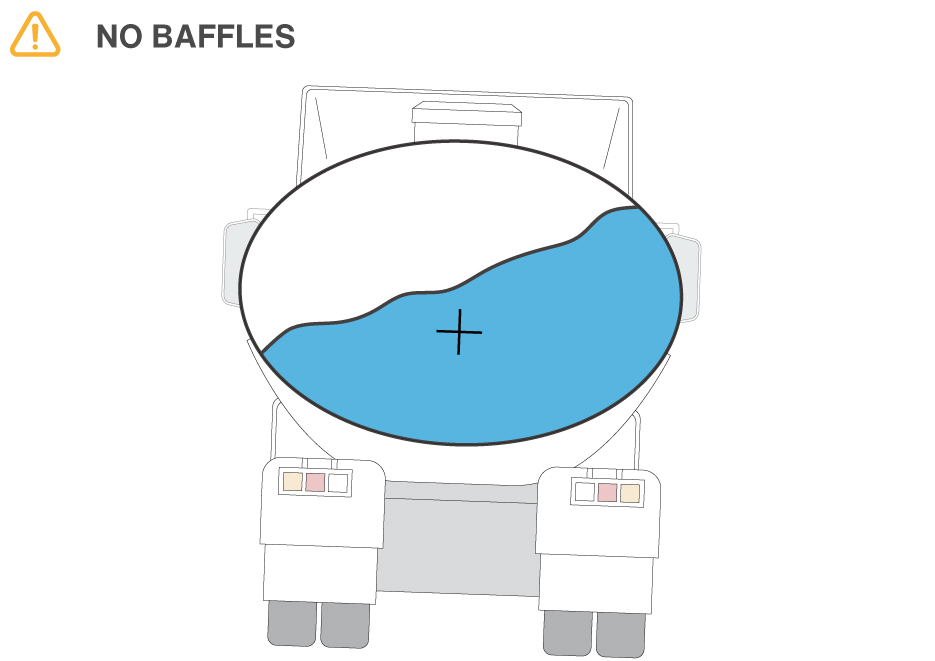

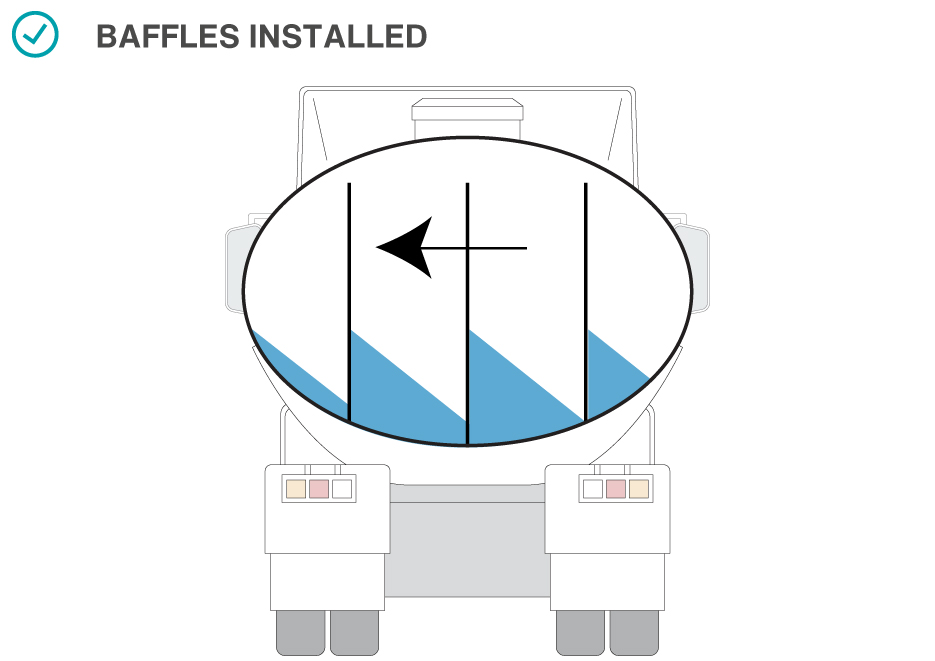

- Tankers – Tanks without baffles or compartments installed allow liquid to slosh freely. In these circumstances liquids can shift unexpectedly, making the vehicle unstable.

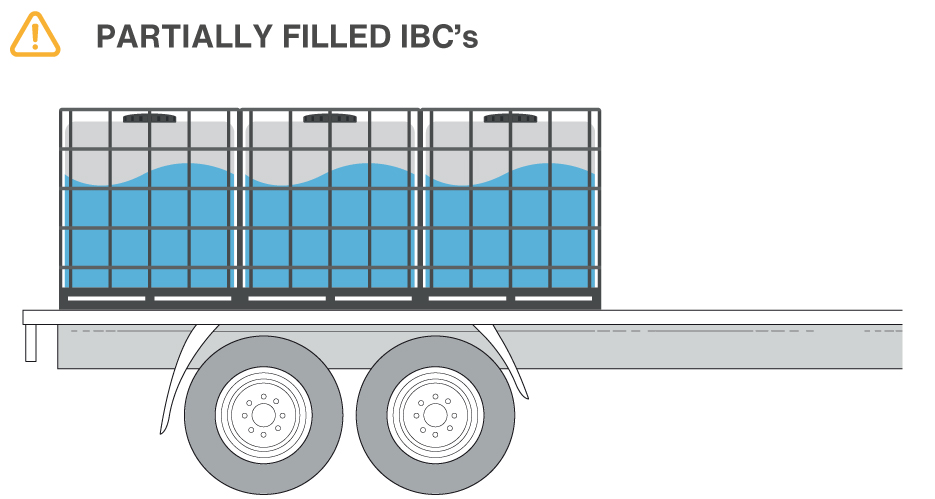

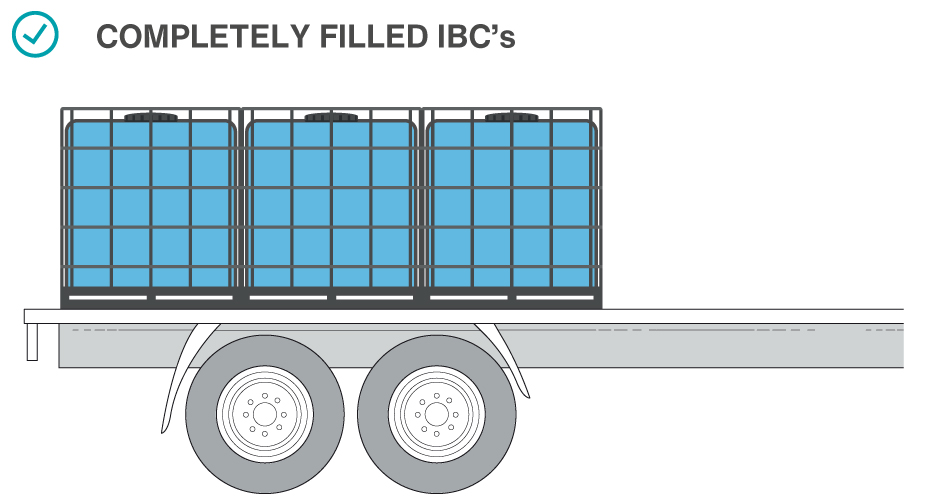

- IBC’s (intermediate bulk containers) – Partially filled IBC’s can affect the vehicles stability through liquid slosh and will add pressure on the load restraint system. Find more information on this topic at Loading Guide – Intermediate Bulk Containers (IBCs).

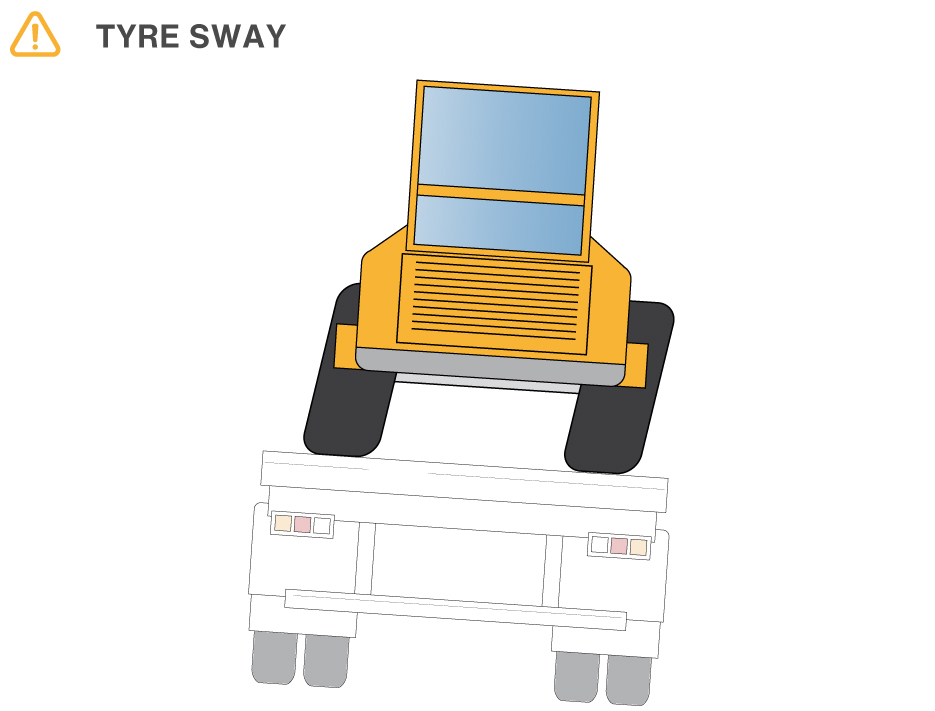

- Wheeled equipment – Flex in tyres can cause the load to bounce after braking or move sideways when cornering. This movement causes wear in lashings and lashing points and in extreme cases can stretch or break lashings or cause lashing points to fail.

Tips to ensure safe transport of live loads

Drive with care

- Take wider and slower turns, maintaining steady acceleration and braking

- Increase the distance between your vehicle and the vehicle in front of you to minimise harsh braking events

- Minimise sudden movements that may cause the load to move excessively

Road features/design

- Avoid clipping gutters and roundabouts

- Take care on negative camber roads, such as roundabouts

Preventing movement

- If liquids are transported in partially filled tanks they should be baffled or have multiple compartments that are either completely full or empty

- When transporting hanging meat, the carcasses must be closely packed to minimise movement or otherwise be restrained

Transport livestock

- Transport livestock in vehicles equipped with purpose-built bodies or removable crates

- Where livestock is carried in multiple deck crates, animals should not be transported in an upper deck until the lower levels are filled

Wheeled equipment

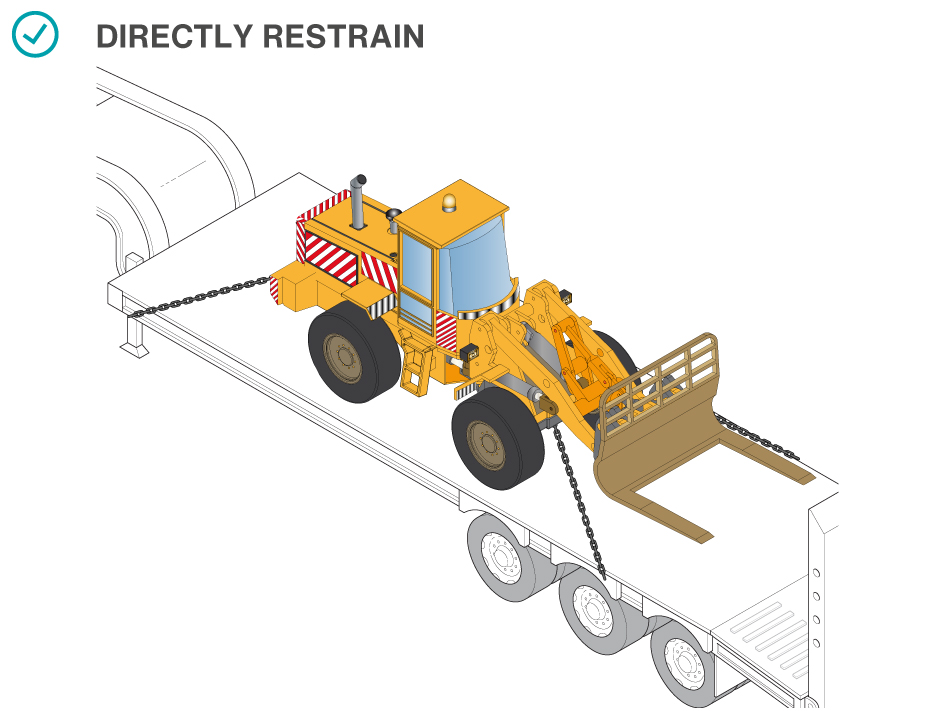

- To prevent bounce/movement, remove the wheels or support the vehicle/equipment on blocks

- Make sure direct lashings are angled at 25° to the horizontal to minimise bounce, and within 30° of the of the carrying vehicle’s centreline

Tips

Risk

Good practice

Risk

Good practice

Risk

Good practice

Risk

Good practice

Note: Live loads can lead to significant hazards if not managed properly. If you are unsure of the safest way to transport live loads, refer to the Load Restraint Guide or seek advice from an appropriately qualified engineer.

Accessibility tools

Accessibility tools